Finishing with a block house inside the house is an opportunity to get a surface that will resemble a wooden log house. Installation works will not require professional equipment and hiring specialists, since the process can be performed independently. A cladding of environmentally friendly products will create a special microclimate and comfort in the room.

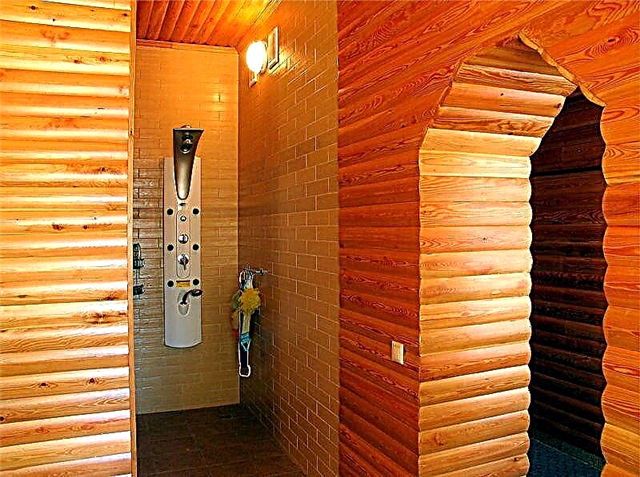

Block house in the interior

Natural finishing material, which has excellent decorative properties, will become a real decoration of any room. The block house is used for the entire interior or part of the room.

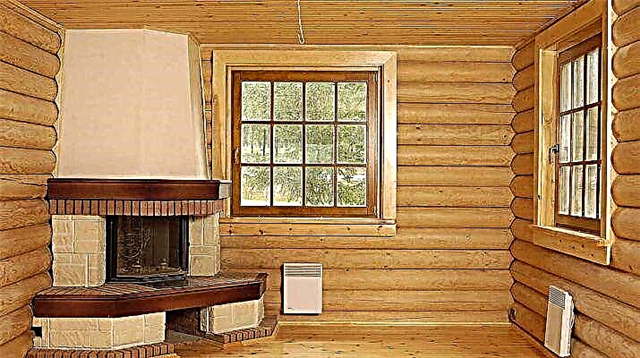

- The living room will become more spacious and comfortable if the board has a light shade. To complement such an interior, you can putty the joints with a darker putty. A clogged harness looks good.

- A small room with small dimensions is faced with a combined method. But if you want to finish the room with a block house, you should completely provide for large window openings or optional lighting.

- An excellent complement to the interior are other wooden details. It can be a staircase to the second floor or an imitation of a ceiling support in the form of a natural log.

This option will be a suitable decoration for the house, which has an external cladding that simulates a wooden log house.

12 photos of the cladding of the interior walls with a block house

How to fix a block house

Fixing parts is a fairly simple procedure. Since the material is identical to the lining, they have the same installation principle. Fastening is carried out directly on the wall or crate, the elements are connected due to the "tongue-and-groove" locking mechanism. Additionally, self-tapping screws are used, with which the fragments are stitched through.

Clamping the panels with clamps is easier than using screws or nails.

Clamping the panels with clamps is easier than using screws or nails.

An alternative method involves hidden fasteners: the parts are fixed using clamps (brackets worn from the groove end and fastened to the base with screws). This wall decoration is much preferable, since you do not need to hide screws.

How to make an external and internal corner connection

To make the inside corner of the block house attractive, you need to make an effort. The joint should be taken care of in advance, because some methods involve the acquisition of additional material.

Methods of internal connection of parts:

- Undercutting. This is the most attractive, but very responsible and complex option. Elements are trimmed with a rounding at 45 degrees, that is, the edge becomes like an angle. This decoration of the house with a block house requires a careful fit. The method has a feature: the lower part of the docking wall is cut in half, and the largest surface with the least number of openings is sheathed first. Installation is best done in a circle, leaving the wall with the main door in the end. After facing the first wall, the elements of the adjacent surface are laid with trimming. The material has a rounded front, so fitting is best done locally. If the fragments are the same size, then you can make a template. All cracks are smeared or clogged with a special rope.

Arrangement of the inner corner with trim looks beautiful, but requires a special tool and a responsible approach

Arrangement of the inner corner with trim looks beautiful, but requires a special tool and a responsible approach

Docking through a beam or with a decorative molding overlay is considered more affordable for a home master

Docking through a beam or with a decorative molding overlay is considered more affordable for a home master

Creating external corners is a simpler procedure. It implies two main options: cutting of the joined parts on each side at 45 degrees and the use of an angular lining.

Block House Choice

There are several types of such material, but special requirements are imposed on the block house for internal work. Therefore, the traditional wooden variety is mainly used.

It includes the following options:

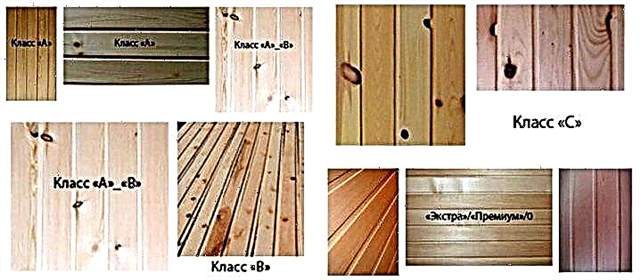

- Elite class products. Such products are of perfect quality, they are free from any defects. This affects the cost, which limits the use of the material.

- Lower in quality is class “A”. Products have minor flaws. The price of products is slightly lower than the previous version, so the use of such a block house indoors is quite common.

- Class “B” finishing materials have many visible defects (falling knots, cracks), therefore it is recommended to use this option for auxiliary or storage rooms.

Cladding “Block House” is classified according to the same principle as a standard clapboard

Cladding “Block House” is classified according to the same principle as a standard clapboard On a note! The cheapest product is considered to be an imitation of a block house made of vinyl and plastic, but such products are rarely used for internal work. The best place to use them are verandas and balconies, if they do not have constant heating and sealing.

When choosing a wooden material pay attention to several basic parameters:

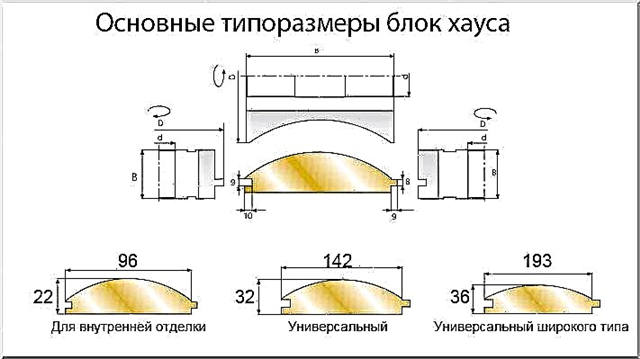

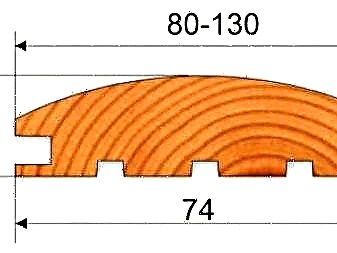

- The size of the parts. For indoor work, it is recommended to use elements up to 10 cm wide, up to 2.5–3 m long (depending on class) and more than 2 cm thick.

For each interior, you can choose your own panel size.

For each interior, you can choose your own panel size.

All self-respecting manufacturers pack wooden cladding in polyethylene

All self-respecting manufacturers pack wooden cladding in polyethylene

Types of finishes

The required amount of material depends on the choice of the sheathing method:

- Full cladding. This method allows you to achieve absolute naturalness. The block house for interior decoration has a semi-cylindrical front part, which imitates log masonry, so the parts are placed horizontally.

- Combination. In this case, the facing board is mounted only on certain walls or their sections. The rest is occupied by other materials: tiles with imitation of stone or brick, decorative plaster.

Combined cladding looks impressive and cheaper

Combined cladding looks impressive and cheaperOn a note! Regardless of the type of casing, products are purchased with a small margin. This will compensate for the percentage of rejects that were not seen at the time of purchase.

Product preparation

To ensure durability of the inner lining, products must be prepared:

- Parts are unpacked and laid out on a flat surface. Placing them vertically is not allowed. This procedure allows the details to acclimatize.

- All elements are evaluated: defects are detected, fragments with serious defects are rejected.

- The material is impregnated with flame retardants and antiseptics. It is recommended to do this before installation, since it is possible to process the entire parts.

- Products are left to dry completely.

If decorative wood treatment with wood stain is planned, then it is carried out simultaneously with the application of protective impregnation

If decorative wood treatment with wood stain is planned, then it is carried out simultaneously with the application of protective impregnationWhile the products are dried, the crate is erected. The frame is necessary to hide defects and curvature of the walls, so all racks are fixed in level. A wooden beam is used for work, its preparation must be carried out in advance according to the above principle. Fixing is carried out on self-tapping screws or corners, the elements are arranged vertically in increments of 35 to 55 cm.

Further work is begun only after preparation.

Material installation

Installation of a block house is not the most difficult, but requires accuracy, task.

- Installation can be started from above or from below, the latter option is more preferable in the absence of professional skills.

It is better for an amateur to sheathe walls from the bottom up, constantly monitoring the plane by level

It is better for an amateur to sheathe walls from the bottom up, constantly monitoring the plane by level

When fixing the panels with self-tapping screws, there is a high probability of chips, especially if the master has no experience

When fixing the panels with self-tapping screws, there is a high probability of chips, especially if the master has no experience

It is desirable to perform block house paneling without the use of corner overlays and profiles, so it looks more organically

It is desirable to perform block house paneling without the use of corner overlays and profiles, so it looks more organically

The final stage of finishing is the coating of the material with varnish or wax. This will give the surface a more beautiful appearance and protect the product from damage.

Material Features

The properties and some external details of a block house are similar to euro-lining. For example, the same method of joining by means of grooves and spikes. Also both types of panels there are special recesses for ventilation on the back. But the outside of the blockhouse does not resemble a lining, but a round log.

Since the products are exclusively natural materials for home decoration, he has several indisputable advantages:

Appearance. The pleasant wooden texture captivates many designers, allowing you to create unique interiors, especially in the growing rustic style,

Appearance. The pleasant wooden texture captivates many designers, allowing you to create unique interiors, especially in the growing rustic style,- Environmental friendliness. Natural material does not emit any harmful substances. The panels are dried naturally, and during the creation of a wood product, it is not subjected to chemical treatment, so as not to harm health,

- No installation difficulties. The design of the boards is designed to facilitate the assembly process. To achieve an excellent result, you don’t even have to call a specialist,

- Can be combined with other materials. This coating will fit into any chosen style without any problems, adding originality to it,

- Light weight. Due to this property, the material can even be used for the inner lining of a balcony or loggia,

- Soundproofing. The walls treated with wood, due to the high density, do not allow sounds coming from the outside to disturb your life and peace,

- Additional thermal insulation. The material isolates the room from external influences - high or low temperature and humidity, in addition, it is able to maintain the necessary microclimate in it.

Unfortunately, even such material has disadvantages:

Fire hazard. To reduce the high flammability of the blockhouse, a specialized solution must be applied to its surface,

Fire hazard. To reduce the high flammability of the blockhouse, a specialized solution must be applied to its surface,- Low vapor permeability. The problem is that over time, fungus and mold may form under the panels. But to prevent problems of this type, it is necessary to create air circulation, including from the back of the boards, and occasionally ventilate the rooms,

- Like any other, this material is subject to deformation. It is necessary to carefully monitor the assembly of the panels during the installation process, otherwise you can accidentally cause damage to the surface.

Types of block house for interior decoration

When choosing a blockhouse for the roomin which repairs will be carried out, you should pay closer attention to size, grade and appearance. Wooden panels used for interior decoration are an order of magnitude smaller, that is, the width of one board is approximately 9 cm, but there are other options for every taste. Such parameters present the room in a favorable light, visually expanding it. If you nevertheless decide to use wide panels, this can ruin the impression, as they visually reduce the space and in some cases create discomfort.

Division of material into categories:

Extra class. There are no cracks, bumps or scratches on the surface of the finish. It is mainly used in fairly expensive houses and luxury hotel complexes,

Extra class. There are no cracks, bumps or scratches on the surface of the finish. It is mainly used in fairly expensive houses and luxury hotel complexes,- Grade A. Usually, this option, due to high-quality performance, is used for processing residential and business premises,

- Grade B. This type of wood already has noticeable defects on the front side. As a rule, this material is chosen for arranging steam rooms and dressing rooms,

- Variety S. It has a rather unpretentious appearance, so it is more suitable for utility rooms - pantries and basements.

In the market you can often find combined types of panels, for example, A-B or B-C. Before the final choice, you should familiarize yourself with the storage conditions of the panels. If the place where the panels are located does not comply with the norms and standards adopted in this area, this may affect the installation of the blockhouse - the tree can split or become twisted.

Panel Tips

To begin with, you should decide in which particular room you will make the upcoming repair - in living rooms or in the office building. Stores provide a wide selection of products that will meet all your needs.

To begin with, you should decide in which particular room you will make the upcoming repair - in living rooms or in the office building. Stores provide a wide selection of products that will meet all your needs.

In the manufacture of finishes from natural materials, coniferous and deciduous trees are involved. For example, the tree has an exquisite design, pine due to the abundance of branches consists of many circles and branches.

But for the interior decoration of the bathhouse, sauna or pre-room, you should choose a covering of deciduous trees, such as linden, aspen or alder. This is due to the fact that, unlike conifers, which, under the influence of high temperatures, emit tar and become very hot, causing tangible discomfort, these disadvantages are much less common for deciduous trees.

Custom trim options

When arranging a house from the inside, sometimes unusual methods of decorating the premises are used.

Finishing inside can be:

- Full, that is, in addition to the walls, the ceiling of the room is also sheathed,

- Combined - one or several walls are exposed to wood paneling, and other materials are used for the rest.

In particular, the blockhouse can perfectly combine with a variety of decorative finishes. Wooden elements are remarkably adjacent to metal products, stone, as well as glass and ceramics. You can easily fulfill any idea - You can combine different types of finishing panels or use textured plaster simultaneously with a wooden coating.

Technology and installation of interior decoration

Before assembling and installing the panels, you do not have to additionally level the walls or process them with any means, because the installation is done directly on the crate intended for this. It is created from 50 mm by 50 mm wooden blocks or slats reaching a width of 70 mm, which are located at a distance of 500 mm to 700 mm from each other. This structure must be leveled using a level or plumb line.

Before assembling and installing the panels, you do not have to additionally level the walls or process them with any means, because the installation is done directly on the crate intended for this. It is created from 50 mm by 50 mm wooden blocks or slats reaching a width of 70 mm, which are located at a distance of 500 mm to 700 mm from each other. This structure must be leveled using a level or plumb line.

When installing and fixing the house block on the wall, make sure that the panels are placed groove down. This is necessary so that condensed water does not accumulate in the recess, thereby damaging the boards. Faults can also be caused bythat wooden products were too tightly joined together.

To begin with, you should choose the option of adapting the panels to the crate, which is directly related to the size of the material. For this, nails, self-tapping screws or special fasteners and clamps are suitable. Self-tapping screws are most often used for attaching wide boards, and nails are suitable for narrower ones.

The parts are interconnected by introducing the outer spike of one panel into the groove of the adjacent one. Please note that the joint can be made as invisible as possible if the spike of all the block houses is placed along the path of a natural light source. Each attached part is attached to the crate with nails or self-tapping screws.

To finish your room as long as possible, it should be treated with a special mixture. First, prime the wooden surface, this will give a reliable adhesion of the panels with a subsequent layer of varnish or colorless paint. Next, it is necessary to allow the coating to dry, in order to subsequently sand it and paint it again.

Proceed to wall treatment can be both above and below. The main thing is that at the edge of the casing there is a small space for air circulation under the coating.

Care Rules

Thanks to modern technology, in our time on the market there are many different compositions created to protect the surface of a block house. For processing walls, primers, varnish or wax are used. Over time, the treated surfaces must be cleaned of accumulated dirt and dust with a damp cloth or vacuum cleaner. Refrain from using detergents and abrasives that are not designed for wood panels.

Thanks to modern technology, in our time on the market there are many different compositions created to protect the surface of a block house. For processing walls, primers, varnish or wax are used. Over time, the treated surfaces must be cleaned of accumulated dirt and dust with a damp cloth or vacuum cleaner. Refrain from using detergents and abrasives that are not designed for wood panels.

The use of paint, stain or varnish can enhance expressiveness and emphasize the color palette of wooden panels. For example, the stain makes an excellent emphasis on the peculiar pattern of the house block, and the use of suitable paint will extend the service life of the boards, but only with annual processing.

The interior decoration of a house block house is very popular. This design solution is perfectly combined with other types of materials, while creating an amazing decoration of the room and can make any style you choose special. The use of wooden panels for interior decoration does not require a lot of effort and time, so you can do without calling a professional worker.

Block house - what is it?

At first glance, the block house resembles the lining that is familiar to everyone, but there are significant differences between these two facing materials. House panels on the outside have a semi-cylindrical shape and after finishing the cladding, the facade takes the form of a structure made of logs. For this reason, they are used as a decorative imitation of wooden walls.

The panels have a flat inner surface with ventilation slots. Installation of block houses is carried out using a thorn-groove-type locking connection, and the final fixation to the lattice frame is carried out using self-tapping screws and kleimers.

Traditionally, a block house is used to decorate the exterior of the building, but in some cases it can be used for interior work. For facades, it is recommended to purchase wide, and for the interior, narrow panels. House panels are faced:

• concrete surfaces,

• frame walls,

• walls made of blocks, timber or brick.

The material can also be used in the restoration of dilapidated buildings. Light sheathing does not exert a large load and does not threaten the integrity of the old foundation. Especially the block house is in demand for cladding of prefabricated buildings: arbors, terraces, household buildings.

What is a block house made of?

For the manufacture of a block house, various materials can be used:

• various types of wood,

• vinyl

• galvanized metal.

Each type has its own characteristics, and if it is allowed to sheathe internal rooms with wooden panels, then vinyl is not recommended for these purposes. Consider each of the materials in a little more detail.

Wooden block house

The material is a wooden cladding panel with ventilation and connecting grooves and special protrusions (spikes) for seamless joining. Most often made from conifers: cedar, larch, pine, as their wood is more resistant to moisture and decay. From deciduous trees such trees as oak, ash and alder are distinguished.

At the initial stage of production, the wood is thoroughly dried under high temperatures, which significantly reduces the moisture coefficient in the structure of the material and prevents the development of the deformation process in the finished product.

In addition to natural decorativeness, natural material has low thermal conductivity, so in a house sheathed with a wooden block house, it will always be warm and cozy.

Vinyl block house

The basis of vinyl house panels are PVC components. The material is manufactured using a special technology, which gives the structure of the panel a two-layer structure. The outer layer provides the decorativeness of the product, and the bottom - strength and resistance to deformation and climatic influences.

The building material made from primary vinyl powder, the primary raw material, has high quality characteristics. A block house made from recycled materials has low stability and is characterized by fragility. One of the signs of using secondary resources, in addition to information from the manufacturer, is the external difference in color between the surfaces of the inner and outer layers of the panels. Specialists categorically do not recommend using material from recycled materials for cladding houses.

Block house metal

The metal siding block house is made of galvanized steel and treated with a polymer coating. To give the panels a resemblance to natural material with the help of offset printing, a pattern imitating wooden beams is applied to the surface. The decorative qualities of this building material are significantly higher compared to natural wood, thanks to a wide range of different colors and shades.

Krovelson company produces block houses "Log", equipped with additional longitudinal stiffening ribs, increasing the strength of the panels and the resistance of the material to stress, it also gives the product the texture of natural wood. Products manufactured at our company's facade and roofing plant have the following advantages:

1. Modern technologies allow us to accurately convey the shape of the log house and the texture of a natural wooden surface.

2. A multilayer protective coating of polymers protects the surface from fading and the negative effects of UV rays.

3. Metal siding "Log" of our production has a low coefficient of thermal expansion and resistance to temperature extremes. Due to these qualities, the material can be used in difficult climatic conditions at temperatures from -50 to + 80 ° C.

4. Simple installation and the absence of the need to align the walls before laying the panels can reduce the cost of lining and the complexity of the process.

5. Siding "Log" is a ventilated facade with improved thermal protection, which reduces the cost of heating the building.

6. Installation can be carried out both from bottom to top, and from top to bottom.

7. It is possible to clad external walls at any time, regardless of the season.

The development of our own production allows us to produce building materials in the volume and size required by the client. The set with panels includes additional materials for the design of cornices, corners, ebbs, doorways and windows. Their presence is a great opportunity to give the appearance of the house a harmonious completeness and presentability.

Advantages and disadvantages of a block house

Each of the types of block house has its pros and cons, but a common advantage is:

• high degree of decorativeness,

• easy installation

• environmental friendliness.

House panels made of wood possess high frost resistance and decorativeness. Natural material is one of their main advantages. With timely treatment with antiseptic and fungicides, the lining will delight for a long time with its impeccable appearance. But, like all natural materials, a wooden surface requires special care and attention. The surface needs periodic updating, painting, varnishing and repair. During operation, the web may undergo deformation or rot. It is also worth noting the high cost and fire hazard of the material.

PVC block house - An excellent budget option for cladding. Unlike a wooden coating, it is not susceptible to decay and infection by a fungus. The panels look very aesthetically pleasing and can be made in any color range. The material is not prone to fire, but in case of fire or the proximity of the source of fire begins to melt and deform. Its sensitivity to temperature changes is slightly lower than that of wooden and metal counterparts. The facade of vinyl is virtually maintenance free, but over time, it may begin to fade and lose its original brightness.

Metal siding "Log" - An example of a harmonious combination of low price and excellent quality. It has high resistance to temperature extremes, and the polymer coating makes the material immune to ultraviolet radiation. Metal siding is absolutely fireproof material.

Like plastic, metal cladding does not rot and does not absorb moisture, but it is very durable and can be used for up to 50 years without losing its attractiveness and color saturation. Among the shortcomings can be noted the low soundproofing qualities of the metal and the severity of the structure.

Installation of a block house

Despite the fact that the installation technology of the facade cladding is considered to be easy and not requiring work, the contractor is required to comply with the basic principles of the technological process. Regardless of which type of cladding is selected, the cladding technology consists of the following steps:

• preparation of the wall surface for work,

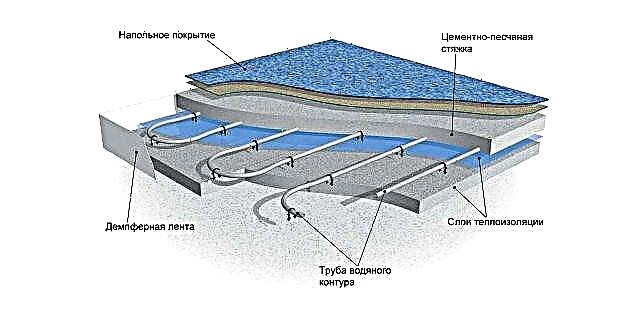

• installation of the crate with the installation of vapor barrier and insulation,

• installation of panels,

• installation of corners, cornices, ebbs and other additional elements.

Compliance with the recommendations of manufacturers specified in the instructions for use of materials will help to mount high-quality and durable protection for your home for many years.

The Krovelson company offers residents and construction organizations of Orenburg and the Orenburg region to purchase all the necessary building materials in one place. In the stores of our distribution network you can buy facade and roofing materials, metal, polycarbonate and other related materials.

We also provide services for the manufacture and installation of rolling and automatic gates, barriers. Our experts will undertake the development and preparation of design estimates and technical documentation and make your dreams come true!

Varieties of material

In the modern construction market, you can find many varieties of block house, which differ in some parameters and characteristics. The main classification involves the allocation of several types of material depending on its quality.

- Extra. Extra-class panels do not have significant defects, they are distinguished by excellent quality and high cost.

- Category "A". Panels in this category are of good quality. A small amount of healthy knots, tar pockets and traces of pests (wormholes) with a width of not more than three millimeters is allowed.

- Category "B". The material may have more significant surface defects. However, flaws should not spoil the operational and decorative characteristics of the panels.

- Category "C". Products of this class are characterized by low cost and the worst quality. The material has an unpresentable appearance and needs additional processing. The panels of this class can finish the walls of utility rooms.

The performance of the block house is influenced by the species of wood from which the material was made.

- Pine. On such a surface there are usually traces of knots that create an interesting pattern. The material can be used both for interior and exterior decoration of houses.

- Siberian fir. This material stands out among other conifers with the smallest weight. Fir contains little resin, so this wood is prone to decay and requires additional treatment with an antiseptic.

- Spruce. This material has a beautiful texture. Unlike pine, spruce has a lighter shade.

- Cedar. Such wood has a pleasant aroma and a good effect on the indoor microclimate.

- Larch. This material is highly durable. Larch contains a large amount of resin, which protects the material from decay.

- Alder. This type of wood is considered one of the most durable and moisture resistant. The performance of alder panels only improves over time.

- Linden. Such a coating is practically not exposed to high temperatures. Most often, a linden block house is used for cladding bath rooms.

- Birch. Wood has a homogeneous structure and is easy to process with paints and varnishes. Using birch panels, you can create an imitation of almost any expensive wood species.

- Aspen. Such panels are not susceptible to decay, they tolerate moisture and are highly durable.

Wood panels can have different lengths, widths and thicknesses. Standard indicators for the thickness of the material are 20, 30 and 36 millimeters. Width can vary from 90 to 190 millimeters. Intermediate values of the width of the produced material are usually 120, 140 and 160 millimeters. The length of the panels is usually two or six meters.

How to choose?

The choice of a suitable block house depends on several parameters at once.

When buying material, the following factors should be considered:

- room area

- interior design style,

- the purpose of the room

- type of surface to be trimmed.

For small apartments or rooms of a small area, it is better to use panels with a minimum thickness. Such material does not "take" a lot of space. For large rooms, you can use wide panels, which will create an imitation of a rounded beam.

The block house looks good in such interior styles as country, rustic, provence, shabby chic. Panels are perfectly combined with other materials, for example with decorative plaster, natural stone or paintwork. Block house can only be finished part of the wall, creating an interesting interior solution.

Panels are quite easy to mount on a wide variety of substrates. Most often, the material is used for facing brick, concrete, wooden or metal surfaces.

The purpose of the room in which the cladding is planned to affect the choice of the type of wood from which the panels are made. In rooms with high humidity, the best option would be moisture-resistant tree species.

When choosing a block house, it is also important to pay attention to its quality. There should be no damage or significant defects on the surface of the material.

How to sheathe: step by step instructions

Wall covering with a block house can be easily done by yourself. Installation work does not require thorough cleaning and leveling of the base, since the panels are mounted on the crate. Before starting the main work, the block-house planks are recommended to be treated externally and internally with an antiseptic and dried at room temperature.

Surface preparation

To protect the base from the adverse effects of external factors and microorganisms, it is necessary to clean it from contamination and treat it with antiseptic impregnation. If there are significant irregularities on the surface, then the wall must be leveled with plaster or putty.

The main preparatory stage before facing the block house panels is the installation of the frame. For the crate, a beam is used, the thickness of which can be from three to four centimeters. The slats are vertically attached to the surface with an interval of 50-65 centimeters using dowels and screws.

First you need to attach the slats in the opposite corners of the room. When installing the beam in the corners of the first, its upper part is fixed. The correct position of the lower part is determined using the building level.

A rope is stretched between the installed rails, then the remaining parts of the structure are fastened, starting from the middle of the wall.

It is more convenient to attach the beam, starting from the top. After complete installation of the structure, you can proceed to the facing work.

Finishing work

After all the planks are securely attached to the crate, it is recommended to level the surface with a grinder. To improve performance, wood also needs to be treated with antiseptic and fireproofing.

The gaps that were formed during installation between the planks and the floor, as well as the planks and the ceiling, must be covered with skirting boards. To give aesthetics to the facing coating, the block house can be treated with paint, varnish or stain.

For surface painting, it is better to use water-dispersion compositions to preserve the natural structure of wood. The technology for applying the paintwork does not differ from the similar treatment of any other wooden structures.

To protect and decorate the panels, you can use a natural wax coating. The surface covered with wax is not so demanding in maintenance. It is enough to occasionally remove dust from it with a dry cloth or vacuum cleaner.

Room Design Examples

Wood looks great in the interior of the kitchen. Bright panels fill the atmosphere with warmth and coziness.

Block house made of moisture-resistant wood can be used in rooms with a high level of humidity. White painted wood panels look great in a Provence style bathroom.

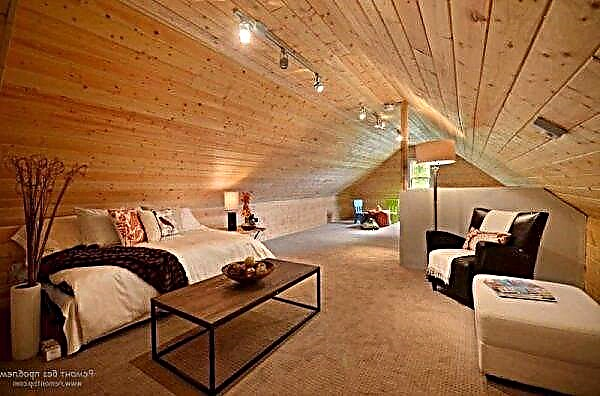

Wooden panels are often used to decorate attic floors. The material does not create a large load on the walls, improves the level of heat and sound insulation.

The block house is used to decorate not only walls but also ceilings. Wide panels with a bright natural texture create an imitation of a country house from a log house.

Wood cover can not only create an atmosphere of home comfort. The block house of dark tones perfectly emphasizes the strict interior of the office.

Decorating the bedroom with wooden panels looks restrained and calm, which contributes to rest and relaxation.

See how to decorate the rest room with a block house in the next video.

Colors

The color of the block house is determined primarily by the material from which it is made. The most popular are the light shades of the block house. So, pine panels have a sunny golden warm hue.

They are optimal for creating interiors in the Scandinavian style, for example, as well as for the kitchen.

A rich color palette is typical for oak products. Depending on the growth method and processing method, the shade of wood varies from white (bleached oak) to almost black (stained).

Walnut looks noble and elegant in the interior. It has a rather dark pleasant chocolate shade, which during operation becomes more saturated.

Another option for a premium block house is beech wood. Its wood has an amazing pinkish tint of varying degrees of saturation - from powder, closer to ivory, to brown with red reflections.

After installation, wooden surfaces can be coated with stain or varnish. They do not change the shade, but make the relief of the tree more expressive. But special paints are able to transform the surface.

Today, compositions are produced, after applying which the usual inexpensive tree in its appearance begins to resemble expensive varieties.

Design solutions

Thin and light block house is suitable for cladding both a city apartment and a country house. Moreover, the latter does not need to have a massive base, sheathing of a frame house is a fairly common practice in private housing construction. Moreover, there are many ideas for cladding.

It is not necessary to sheathe the entire room with a block house, it may be a certain area. The material goes well with stone, brick, and tiled surfaces.

The block house can be combined with other wooden textures (board, lining), as well as delicate noble textiles. This warm natural material blends harmoniously with wrought iron and glass elements.

A block house is the best option to recreate the atmosphere of a house in the Russian style - an expensive merchant or more concise, in some ways even ascetic peasant. Interior styles such as chalets and the atmosphere of a small hunting lodge are also impossible without the use of wood.

The block house in this case is an affordable and convenient option.

Due to the environmental friendliness of the material, it can be used not only in the living room and corridor, but also in the bedrooms, dining room and even children's rooms.

Covering the cabinet with a block house will add to it rigor, respectability, emphasize the status and good taste of its owner. It is better to select material of a darker shade, combining it with furniture in tone, genuine leather, original design elements.

For living rooms and bedrooms, it is better to choose lighter options, perhaps a combination of several different types of block house. If panels for logs are used, they will attract attention. In this case, furniture and accessories should have simple shapes, be quite restrained.

The combination of stone, wood and glass looks attractive in the living room.

When decorating the bathroom with a block house, it can be turned into a luxurious boudoir. Usually light material is also used here. As an option - bleached wood. For greater aristocracy, you can add dark "logs". Choosing this type of lining, you should carefully treat the wood with hydrophobic compounds.

However, in this case, too, it will not last as long as in rooms with normal humidity.

Material selection

You can get attractive and high-quality lining only if you select the right material. For interior decoration of rooms choose a block house from both coniferous and hardwood.

The former contain a large number of resins and essential oilsthat provides a natural antiseptic effect. In addition, they bring a unique aroma of coniferous forest into the house. Usually they use spruce, which has a large number of knots, which creates an interesting pattern. The pine tree pleases with an attractive amber-gold hue, the room decorated with such material looks warm and cozy.

When choosing a coniferous block house, it should be remembered that it is not suitable for rooms with high temperatures (bath, sauna, steam room), since the release of resin begins with increasing temperatures. When heated, it can cause burns.

Hardwood is equally popular. It is necessary to choose such varieties that demonstrate strength, resistance to decay, warpage. These include oak, aspen, linden.

But the use of birch is better to refuse.

As for the appearance, the block house can imitate a beam or log. The first in the section forms a square, the second - a circle. The block house under the log allows you to simulate the surface of natural log walls and looks very original.

For interior decoration, panels with a width of about 8-10 cm are usually selected, while for external cladding - a wider option, that is, 20 cm. However, this is not a mandatory rule, and if necessary, you can choose a wide block house for the room .

The standard length of the material ranges from 2-6 m, should be selected based on ease of installation and design features. So, with the help of long and thin light strips, you can visually make the room larger. The cost of the material depends on the length parameter - the longer the bar, the more expensive it is.

As for the thickness of the material, 2 cm will be enough for indoor use. In general, the trims can have a thickness of 2-4.5 cm.

Having decided on the size and appearance of the panels, you need to find out which class they belong to, since this largely determines the quality of the products.

Premium-quality panels are classified as Extra. They do not have knots and inside pockets; they are cut exclusively from the middle of the trunk. As a rule, such decoration is used in luxury premises, and its cost is high.

Class A and B panels demonstrate fairly high quality. They have a small number of knots, blackouts, but at the same time they are suitable for decoration, they look neat and noble, they have a more affordable price.

There is also a class C material that is unsuitable for use as a finishing material.

A high-quality block house on the inside has 2 longitudinal cuts, which are necessary to protect the panels from deformation.

Step-by-step instructions for finishing

For work, you need to prepare the necessary tools and materials. The latter must be immediately purchased in the required quantity (and even with a small margin), since products of different lots can externally vary.

Before using wooden elements, they need to give time to lie down in room conditions for 2-3 days, especially if there is a large temperature difference outside the window and in the room.

Before use, wooden building materials are usually impregnated with flame retardants and antiseptics to increase their durability. The entire installation process can be divided into stages.

Do-it-yourself installation

After completing the installation of the frame, you can begin to fasten the block house, as fasteners, self-tapping screws or kleimers are used.

First, in the bars, you need to make holes corresponding to the places of entry and the diameter of the screws.

Correctly mount the block house on top, the first board is placed with the spike up. It is fastened only with self-tapping screws, and already subsequent panels are first latched with it, and only then additionally fixed with self-tapping screws. Thus, all surfaces should be sheathed.

When installing the cladding panels with your own hands, it is important to remember the need to leave a gap of 5 mm on the verge between the ceiling and the wall, wall and floor. These gaps provide ventilation for the system.

Sheathing as a whole does not require professional building skills, because each panel has a thorn-groove mount. First, the panel must be mounted in the corresponding groove (holding it at an angle of 45 degrees) of the previous element, and then fixed with screws.

Docking

Docking the corners, at first glance, may seem complicated, but this is not entirely true. You can produce it using special corners (a simpler option, but requires the purchase of additional elements) or by making cuts at the ends of the panels at an angle of 45 degrees.

In the first case, it is necessary to lead the ends of the boards to the outer or inner corner. After that, you can assemble the remaining wall panels, and then mount the ceiling and floor skirtings. In the second case, it is important to join the boards of perpendicular walls in about the same way as when the wallpaper is glued.

Painting

The final stage (as well as preparation for further surface painting) is grinding. To do this, it is more convenient to use a grinder, first with a larger grain size, and then with fine sandpaper.

The next stage is the application of antiseptics and flame retardants. Despite the fact that before installation, the material was already impregnated with these compounds, it is this technology that guarantees an increase in fire resistance and biostability of wood.

To give the surface a glossy or dull sheen, as well as protect the surface, you can use stain or special varnishes. They emphasize the texture of wood without changing its shade. To give surfaces a different color and even achieve imitation of a more expensive wood species, special paints allow. You can paint the surface with a roller, and in hard-to-reach places (in the corners) - with a brush.

Useful tips from the pros

As already mentioned, the methods of fixing a block house can vary - it can be mounted on kleimers, metal staples or self-tapping screws. The main thing is that all metal elements have a corrosion-resistant coating.

It is permissible to use isospan or its analogues as vapor barrier. Mineral wool or penofol can act as a heater. It is better to refuse to use polystyrene foam insulation.

If you want to decorate the inner surface of a tree, the use of a block house made of wood is not the only option. Today, vinyl and polymeric materials are produced that imitate as closely as possible a wooden beam or log.

Appearance. The pleasant wooden texture captivates many designers, allowing you to create unique interiors, especially in the growing rustic style,

Appearance. The pleasant wooden texture captivates many designers, allowing you to create unique interiors, especially in the growing rustic style, Fire hazard. To reduce the high flammability of the blockhouse, a specialized solution must be applied to its surface,

Fire hazard. To reduce the high flammability of the blockhouse, a specialized solution must be applied to its surface, Extra class. There are no cracks, bumps or scratches on the surface of the finish. It is mainly used in fairly expensive houses and luxury hotel complexes,

Extra class. There are no cracks, bumps or scratches on the surface of the finish. It is mainly used in fairly expensive houses and luxury hotel complexes,