In search of an optimal heating system, real estate owners are increasingly paying attention to a system such as underfloor heating. This is a special heating element that is mounted under the surface of the floor. In this case, it is possible to choose various types of systems. On sale are water and electric underfloor heating, the choice of which depends on the specifics of the room.

Like any other heater, the system may fail. Improper operation or factory defects can cause damage to one or more of its elements. Learn how to repair underfloor heating, help the advice of professional masters.

System features

There are two main varieties of underfloor heating. These are water and electric systems. With proper installation and operation, they are characterized by a high level of reliability. The service life of both pipes and heating wire can reach 50 years.

Repair of underfloor heating may be required earlier if the integrity of one of the elements of the system is compromised. It should also be borne in mind that with the purchase of any structural elements of insufficient quality, the risk of breakdown increases at times. This applies to both pipes or wires, and the control device (thermostat).

With mechanical damage, power surges in the network, various malfunctions can be observed. Their elimination may require significant expenditures of time and effort. To avoid this, it is necessary to carefully study the manufacturer's instructions for such equipment. All of its items must be strictly complied with.

Troubleshooting

Do-it-yourself repair of underfloor heating must begin with a search for damage. The cause of the malfunction can be determined in the area of the heating element, thermostat or sensor.

If the installation was carried out in the room, which involved drilling a base of a room with a drill, the wire or pipe is most likely mechanically damaged. If everything becomes immediately clear with the water floor (water flows out of the system), then the electrical wire requires resistance measurements. The manufacturer indicates this indicator on the package.

The cause may be a breakdown in the temperature controller. If the indicator does not light, heating to the required level does not occur, you need to disconnect the thermostat from the circuit and connect the wires to the network directly. If the floor begins to heat up correctly, then the problem lies precisely in the control device. A breakdown of the remote sensor can also be established by measuring the resistance. It should be between 5 and 30 kΩ. This value is also indicated in the instructions.

Improper operation

Repair of the underfloor heating electric or water will not be required if the system is properly installed and operated. All the nuances are indicated in the instructions. There is a high probability of breakage if the craftsmen laid a wire or pipe on a dirty surface on which foreign objects could be, walked on a heating element in hard shoes or dropped heavy objects on it.

The electric wire should not be mounted close to other heating devices (fireplace, radiator), and also under furniture without legs. In these places it can overheat. Also, you need to choose the size of the wire according to the size of the room. If the master cuts the heating element and installs a coupling, the strength in this place will be lower than during factory assembly.

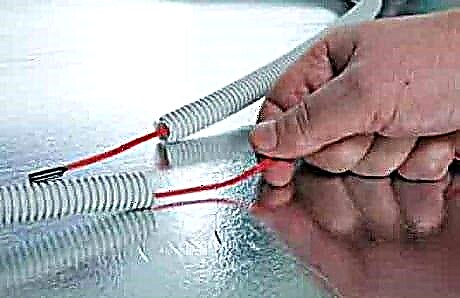

The sensor is installed in a corrugated pipe to be able to dismantle it if necessary. Cable resistance is measured before and after installation. Regardless of the type of system, a plan is drawn up that clearly shows the location of the wire or pipes under the floor. Otherwise, breakdowns and difficulties in their elimination are guaranteed.

Water Floor Repair

If the underfloor heating for some reason fails, a coolant leak will appear. In this case, you must immediately turn off the circulation in the system. Repair of the floor heating pipe may be required due to drilling the base of the room with a drill. It is necessary to leave the drill in its original position.

After turning off the coolant supply, you need to remove the layer of screed around the pipe. A piece of pipe with a hole is cut out. To prevent dirt from entering the system, it is recommended to insulate the ends of the heating element. Then they are flared and put on fittings. The design is pressed in.

On the other hand of each fitting, you need to install a pre-prepared piece of the whole pipe. Connection points are also pressed in. If the pipe length is large, the excess must be cut off. Turn on the coolant supply. If there is no leak, the system is filled with a screed.

Does not heat the electric wire

Repairing a water heated floor is easier. To find the cause of the malfunction in this case is also not difficult. It is more problematic to repair an electric underfloor heating.

After conducting resistance measurements, a deviation of even 5% from the value specified by the manufacturer refers to the incorrect operation of the wire. In this case, it is better to consult a specialist. Those wishing to carry out repairs themselves need to purchase special equipment.

If the cable burns out, a special device will help you find the place of breakage. It will allow you to view the wire in the cable tie. To do this, the system is disconnected from the power supply. The resistance between core and braid should be 1 ohm or more.

Debugg

Even after a breakout location has been found, the correct troubleshooting must be completed. Repair of the electric underfloor heating after determining the location of the malfunction requires removing the screed layer. After that, the burnt (or dangling) section of the wire is stripped to the core.

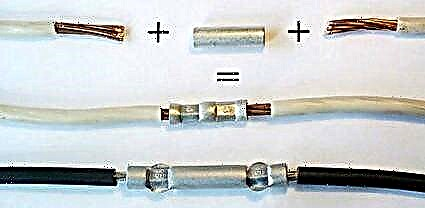

Next, you need a special sleeve. The fact is that the vein has several special shells around it. Therefore, to connect the heating element, like a normal electric wire, will not work. The sleeve must match the diameter of the wire.

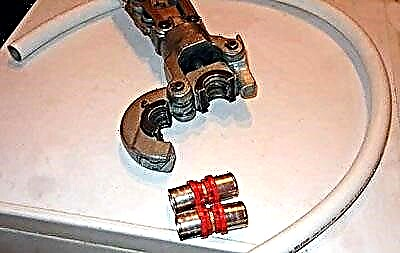

The sleeve is crimped with special pliers. The junction is also additionally protected by a shrink sleeve. It is heated with a construction hairdryer and cooled to room temperature. In this case, the coupling will be compressed, qualitatively sealing the junction. Then the system is again poured with a solution.

Thermostat malfunctions

Repair of underfloor heating in an apartment may require the elimination of defects in the thermostat. In this part of the system, malfunctions occur much more often than in the heating element itself.

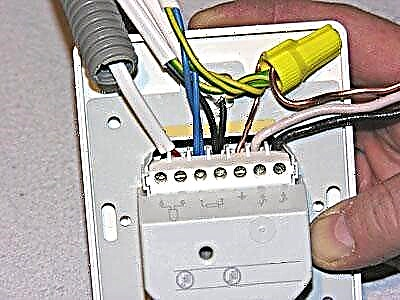

If the indicator does not work, the floor does not heat up to the desired temperature, or the device does not turn off at all, it is worth examining the fastening of the wires. Sometimes they are not clamped well by the terminals. In this case, malfunctions of a different nature may be observed. Tightening the wires in the terminals, you can fix system problems.

Repair of the sensor and thermostat

If after checking the contacts the device does not work correctly, it is necessary to replace it. Repair of underfloor heating in this case will require the purchase of a new sensor or thermostat. It is not possible to fix electronic malfunctions independently.

A faulty sensor (determined by measuring resistance) is removed from the corrugated pipe. You need to purchase a new device of the same type as it was installed previously. If the sensor was walled into a screed (violation of installation technology), the owners can install another thermostat that will respond to fluctuations in air temperature.

If the regulator itself fails, you will have to contact the service center (if the warranty is valid) or purchase a new device.

Having considered how the repair of underfloor heating occurs, you can eliminate the cause of the malfunction yourself. Following all the instructions of the instruction will help to avoid troubles in the future.

Diagnostics of a warm floor - how to find a cliff

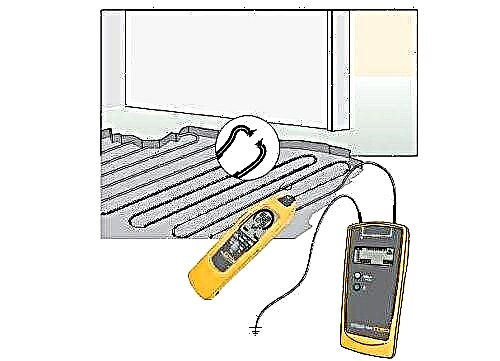

How to check if the cable of the electric underfloor heating is broken? For these purposes, you must use a multimeter. This is such a digital device that is very familiar to people associated with electrics.

If it turned out, so that the resistance is much greater, because what is indicated in the passport, then there is nothing left but to find a break or damage to the electric underfloor heating.

It should be noted right away that the event is quite complicated, especially if ceramic tile or other facing material has already been laid on the warm floor.

To find a cliff of the warm floor, it is easiest to use a special device for this, exactly the same as for detecting hidden wiring in the walls.

Repair of a punched cable of an electric floor heating

After the area in which the electric heated floor is punched is cleaned of flooring and concrete mortar, it is possible to repair the punched cable of the electric heated floor.

For these purposes, it is necessary to have a copper sleeve for crimping and a heat shrink tube. After a break in the electric underfloor heating is connected by a copper sleeve for crimping, it must be protected with a heat shrink tube.

Principle of operation

The underfloor heating system can be used as additional heating of a room or the only source of heat in it. If homeowners prefer the second option, then it is only professionals to entrust the installation of the system. Otherwise, you can make an irreparable mistake and leave the house without heating.

Professional craftsmen can easily choose the latest materials, have the necessary equipment for installing a warm floor, begin how to install it quickly and without difficulty. If, nevertheless, it was decided to mount the electric floor yourself, it is worth exploring the principle of its operation. Let's start by studying the basic elements of this design:

- materials for hydro and thermal insulation of the base prevent heat leakage in the system,

- heating elements - pipes for circulating heated water for a water floor, cable mats or cables with self-regulating heating conductors for electrically floors, infrared film in the case of an infrared floor,

- temperature sensor that allows you to control the level of heating of the structure,

- fasteners

- heat-conducting layer and concrete or other materials,

- flooring,

- a pump that provides the forced supply of heat carrier for the water floor or the power cable of the electrical panel in the case of an electric floor.

Thus, underfloor heating can be made of different materials and using different technologies. But the principle of operation of such systems is similar: thanks to a power source, the floors heat up and become very comfortable even for bare feet.

If the system fails, a number of repairs are required. To do this, you can call the wizard or try to cope on your own. Doing the repair of a warm floor with your own hands is quite real, the main thing is to read that article to the end.

Faults and methods of repairing a warm floor

The underfloor heating system is characterized by a long service life, reliability, high comfort. But it may eventually fail. For example, if a mistake was made during the installation work or one of its elements was damaged. In this situation, you can try to determine the cause of the breakdown and fix it yourself. After all, repairing a warm electric floor with your own hands allows you to save on paying for the services of a qualified craftsman.

Experts insist that initially you need to find the causes of the problem. This will allow quickly and without additional difficulties to cope with the repair. We describe the most commonly diagnosed warm floor dysfunctions below.

Damage to the heating element

If you notice that the underfloor heating does not heat up, you should definitely check if there is a defect in the operation of the heating element. After all, the operation of the heating system is the basis of the technology of such a floor covering.

The cable of electric floors can be damaged by drilling during repair work, which will lead to the breakdown of the entire heating element. Damage to the cable can be triggered by other causes. In any case, it will be necessary to eliminate the defective area.

To do this, remove the cable tie at the point of cable damage, carefully strip the torn or damaged section of the wire, and then connect the two ends with a sleeve of a suitable diameter. The joint must be sealed with a special heat-shrink sleeve. It reliably protects the joint, since it has the property of expanding when heated and contracting when the temperature decreases.

After restoring the integrity of the cable, it will be necessary to restore the screed layer with a not very thick cement mortar. Do not turn on the system for a month after repair! Otherwise, the integrity of the heat-conducting material will be compromised.

Temperature sensor failure

If the installation design scheme was not broken, but there are still problems with it, there may be a reason for the floor dysfunction due to the malfunction of the heat sensor. For example, the sensor indicates high temperature, and the flooring is completely cold. Or the system is working, and the temperature indicator is either working or dying. It is also possible that you notice that it is simply impossible to lower or raise the temperature of floor heating. So, the warm floor does not work, since the temperature sensor of the system has gone out and is inoperative. In this situation, the heat detector must be dismantled and replaced with a new one, which is deepened into the corrugated sleeve until it stops. Since in most cases repairing a thermostat for a warm floor is more expensive than buying a new part.

In order not to make a mistake when choosing a temperature regulator, it is better to take a dismantled sensor with you to the store. By showing it to the seller, you can be sure that you will get exactly the same, but working. Also note that experienced craftsmen advise equipping floors with several temperature sensors so that if one of them breaks down, you do not have to turn off the entire system.

Water floor defective

Water floor pipes are extremely difficult to damage. This is possible only if its integrity is violated with a grinder or puncher during repair work. If this still happened, turn off the water, pull out the unit disk. The water in the pipe with the defect will have to be drained completely, after which the floor is removed in the area of the defect. The integrity of the damaged section of the pipe is restored using a special sleeve, which is worn on the pipe and tightened securely on it.

You can also cut the pipe with a grinder and reconnect using the fitting. When the cause of floor heat dysfunction is not due to a pipe defect, you can repair the water floor yourself.

To do this, you need to carry out a number of operations that will fix the problem:

- Check the water taps for blocking water access. If they are closed, just open them,

- check the pump is working - if everything is normal, you will hear a little noise and feel a slight vibration when you touch the unit,

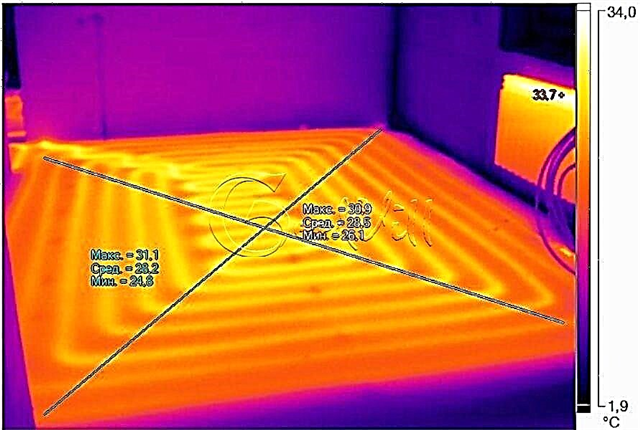

- Analyze for leaks due to damage to the system, using a special device - a thermal imager. It will help determine where the leak occurs in the system.If a defective area is detected, it will be necessary to take measures for its thermal insulation,

- understand if air bubbles have entered the system, because the area that is “airy” will remain cold. You can correct the situation using a water diverter. It is installed on the collector.

Common installation errors

Electric underfloor heating needs to be mounted according to a scheme specially developed by the designer. This will ensure reliable electrical conductivity and prevent the risk of interruptions or short circuits. If an error occurs in the installation diagram, the system will certainly fail. That is, repair underfloor heating is required mainly in those cases where errors were made during installation. That is why it is so important not to disrupt technology and perform all operations sequentially.

Let us describe the typical mistakes of people who installed a warm floor on their own further.

| Typical problem | What leads |

| The cable is laid without taking into account the area where the furniture will be installed | Recall that under the furniture a floor heating system is not laid in order to avoid the risk of a fire from overheating of furniture. |

| The heating cable was purchased with a margin, and then they cut the extra length on their own | Such actions reduce cable strength, which degrades the quality of the system. |

| Flooring after cable laying is uneven | This leads to uneven heating of the floor surface. |

| The system starts until the screed is completely dry | Such a rush leads to rapid deformation of the screed, a violation of its integrity, the formation of voids and problems with the thermal conductivity of the structure. |

What to do if you cannot determine the cause of the malfunction

It can be quite difficult to determine the cause of problems with the electric floor. In this situation, it will be necessary to make voltage measurements, and then compare the obtained value with the operating voltage from the technical documents to the device. Results should not differ by more than five percent from the value in the documentation.

In addition, it is worth examining the power-on indication. This is done by determining the voltage at the terminals when the light is off. In the absence of voltage, we can state that the contacts of the temperature sensor are weakened, damaged, or problems with the thermostat. You will need to analyze the remote temperature sensor by disconnecting it from the thermostat and measuring the resistance level. This data should be within the range of 5 to 30 kOhm. Do not forget to turn off the heating elements beforehand!

If the temperature sensor is serviceable, a cable break can be detected. In order to finally make sure of this, it is worth measuring the resistance of the cable, as well as the insulation. The data obtained must be verified with the values from the technical data sheet. If the cables are broken, they will be significantly lower than normal.

Causes of malfunction of underfloor heating

It will not be difficult for specialists to identify the cause of the failure of electrical equipment, especially if initially you turn not to a random “master” by announcement, but to a specialized company that installs, calculates, tests and repairs underfloor heating. Thanks to professional equipment, they will be able to immediately detect a malfunction and restore the operation of the heat supply system in the shortest possible time. Including, if you need a complete replacement of the heated floor in the room.

Most often, when repairing a warm floor, specialists have to deal with three main problems.

Thermostat malfunction

The temperature controller is out of order or its settings are lost. This is the main reason why underfloor heating does not work at the beginning of the heating season. In the summer they are turned off, completely de-energized and safely forget about it. Also, the thermostat may fail if dust or moisture gets into it, which will lead to the operation of the automation and blocking of the entire system.

Thermal sensors are out of order

Be sure to check the outdoor temperature sensors that measure the temperature in the room and the heating level of the cable itself. If they give incorrect indicators, a significant excess of temperature, the automation blocks the heating of the cable, believing that it is already quite hot. With this problem, it is necessary to replace or completely turn off the temperature sensors, after which the system will again be ready for operation.

Cable break (damage to heating mats)

To detect a rush, individual sections of the system are tested for troubleshooting. This procedure involves the partial or complete removal of screed and flooring laid on top of underfloor heating. After the gust is detected, the damaged ends of the cable are removed, they are stripped and connected with each other using sleeves. At the junction of the parts, a thermal coupling is installed, after which the screed and flooring are restored. If such a problem arises, the price of repairing the warm floor will be quite high, and all work will take from several days to 2-3 weeks (taking into account the solidification of the screed).

In some cases, after examining the system by a specialist, it may be found out that the heated floors have become unusable or their quality does not meet safety standards, and the installation was carried out with gross violations, which caused damage to the heating mat. In this case, the master recommends that you completely replace the underfloor heating system in order to avoid further malfunctions and more serious problems (short circuit, fire, electric shock).

In preparing this material, data from a specialized company were used. ODO “ElectroTeploMontazh”. According to the data on the official website, the company, among other things, provides services such as repair of underfloor heating cable, here (on the official website) you can also find out the price of repair of underfloor heating.

Three main causes of malfunction of underfloor heating

The design for heating is a reliable system. The term of use of heat-insulated floors, according to the set technological parameters, without major repairs is calculated at least for 10 years. Although each electrical device that is operated continuously has not only its advantages, but also possible technological disadvantages. Causes of malfunction in heating:

- temperature regulator

- open cable

- malfunction in the temperature sensor.

Electric floor repair and troubleshooting

Floor heating works on the principle of any electric heating device. The air in the room warms up from the heat given off by the floor, which has heating elements located below the surface of the warm floor. Elements or a special electric cable heat the floors with electric energy. If a malfunction in the heating occurs, it is necessary to carry out diagnostics to eliminate them.

Temperature controller

The temperature controller performs the function of passing electric current and supplying it to the underfloor heating system. Being not only a switch, the temperature controller is responsible for the strength and quality of heating. Upon reaching the specified nominal temperature parameters, the device automatically turns off and turns on after the maximum decrease in temperature in the heating elements. Therefore, in the event of a malfunction of the device, the floor covering will cease to heat up or overheat very much.

Floor sensor

If the floor sensor is located very close to the heating element, it starts to turn off before the entire heating system warms up. Since the adjacent element warms up earlier and acts on the sensor. Provided that the base of the system cannot warm up at a given power, the floor sensor starts to work without intervals and shutdowns.

Ultimately, round-the-clock operation of the device leads not only to increased consumption of electric energy, but also to its malfunction due to excessive workload.

Heating element or cable malfunction

One of the reasons for the breakdown may be a break in the electric cable or heating element. Cable and element breakage is possible in case of integrity violation during installation work. During subsequent operation, the constant pressure from stepping on a damaged place, the electric cable or heating element is destroyed.

To detect a malfunction, it is necessary to measure the resistance readings. According to the specified parameters, the resistance should not exceed the nominal parameters specified in the technical passport of the electric floor system. If the resistance reading is more than 5% higher, then the cable is damaged. In infrared heating, the heating element is more often damaged according to the same principle: from sharp heels or excessive pressure on the floor.

Search for damage to the heating cable

After disconnecting the system from the mains, disconnect the cable from the thermostat. Using a high-voltage generator, determine the place of cable breakage, since the effect of an electric arc will be created at the place of failure.

You can also use an audio detector or voltage tester to find where the cable is torn. At the place of failure from the audio detector, a characteristic sound is produced, similar to the sound during the operation of the metal detector.

Setting the thermostat for infrared warm floor

Sometimes a weak contact of the connected wires to the thermostat on the terminal strip can cause a malfunction, that is, the floor will not heat up to the set temperature. To eliminate this drawback, it is enough to tighten the screw connection tightly and restore insulation.

Installing a repair sleeve on a heating cable

If the heating cable breaks during repair, it is imperative to use a heat-shrink sleeve that creates the perfect insulation at the cable junction. When performing repairs, it is necessary to warm the clutch with a stream of hot air, you can use a regular hair dryer, after the clutch is put on the joint. Under the influence of hot air flow, the coupling will significantly decrease, tightly closing and isolating the junction.

Do-it-yourself repair of the heating cable under the tile and under the screed

The sequence of actions when performing repairs:

- Having determined the location of the heating cable rupture, it is necessary to raise the flooring at the fault location. Depending on the material from which it is made, the coating can be raised with a whole strip. If the floor is made of tile, it must be removed, being careful not to damage.

- Then, having read the installation diagram of the heating cable, carefully break the concrete screed. For ease of repairing cable breaks, it is important to free a sufficient length.

- After stripping the cable at the place of rupture, connect it and tightly clamp the connection place with pliers, then put on a special sleeve to create the strength of the connection. Insulate the cable with shrink sleeves.

- After the control verification of work, a concrete screed is performed and after drying the floor covering is restored.

Prices for the repair of underfloor heating

The price for repairing floor heating depends on:

- region of residence of the customer services,

- causes of failure and price of the replaced item,

- the size of the concrete screed and restoration of the floor covering.

The final cost of the work is determined after the diagnosis and troubleshooting.

Breakdown prevention

If you strictly follow the recommendations of professionals and the operating instructions for the electric heating system, you can avoid malfunctions and achieve a long service life of the warm floor. There are a number of technological measures, the implementation of which with the installation of electric heating initially guarantees good work.

The main stage is the correct selection of qualified specialists for installation. Compliance with the rules for installation:

- making the right measurements and calculating the required power,

- selection of the cable cross-section according to the size of the room, since wire cutting significantly reduces its strength,

- cutting infrared film strictly according to the markup,

- selection of cable mats, their cutting is unacceptable,

- fulfillment of technological parameters during thermal insulation,

- Do not install a warm floor under furniture or household appliances to prevent overheating,

- it is necessary to place the sensor in a special corrugated pipe to protect it from damage,

- compulsory testing before concrete work,

- Do not start operation until the screed has completely dried.

It is not difficult to repair the floor heating system from electricity, having the necessary skills. An important stage in the repair is not only the correct diagnosis of the malfunction, but also the sequence of the repair to avoid fire and a life-threatening situation.