Decorative plaster is a finishing material that began to be appreciated only a few years ago. In the classical sense, plaster is designed to level the walls, prepare them for applying the topcoat. The fact that the same mixture can serve as the finishing layer causes two reactions at the same time in people - delight and misunderstanding. Let's try to figure out what are the features of decorative types of plaster, and how to apply them in the interior of an ordinary residential apartment.

How is decorative plaster different from usual?

At its core, plaster is a mixture of sand, lime and cement. To give it certain properties, various additional components are added to the composition. Thanks to them, the plaster layer can become more durable, waterproof, textured, etc.

In general, decorative stucco mixtures can be divided into several groups depending on the composition:

- silicate

- silicone

- acrylic

- mineral mixtures.

Each of these groups has its own characteristics both in appearance and in properties. Some are better suited for outdoor use, others can even be used in kitchens and bathrooms.

To better understand the differences between these mixtures, it is worth paying attention to the list of common additives and the properties that they give to the plaster:

- Acrylic, silicone and latex give the mixture wear resistance, vapor permeability. Walls with such a coating begin to "breathe", which is great for rooms with high humidity or rainy regions. The finish will be durable and easy to clean.

- Silicate glass in liquid form gives plaster not only strength, but also moisture and dirt-repellent properties. Such mixtures are characterized by good refractoriness.

- Marble, quartz, etc. crumbs are added to the plaster to give it a pearly, glittering structure. Such mixtures create an imitation of natural stone on the walls.

- Gypsum and lime as part of a decorative plaster mix are designed to make it more durable and durable.

- Cellulose fibers, metallized yarns, colors, pigments, etc. are added to the mixture to give them special decorative properties.

Plaster mixes in construction stores are classified by application methods, destination (exterior or interior work, bathrooms or living quarters, etc.), decorative properties. Choose the option that is suitable in a particular case is not difficult.

A variety of textures of decorative plaster

The way a plastered wall will look after applying the last decorative layer depends on many factors. For example, the particles included in the mixture, the tools used to apply the plaster, certain techniques for working with it.

According to the decorative properties, plaster can be divided into several types:

- Textured blendscreating imitation of natural materials on the surface of walls,

- Structural, with a filler of natural stone chips of various fractions,

- Venetianinvolving the use of special application techniques.

In living quarters, you can use any of these types of stucco mixes, depending on what design goals you pursue. The interiors in authentic styles complement well the imitations of stone or wood, especially considering the fact that plaster is an environmentally friendly material. In minimalistic and loft interiors, simple structural mixtures are often taken as the basis, which will serve as an excellent background for designer furniture or decor.

For those who like luxurious interiors or want to add a “twist” to their living quarters, Venetian plasters, which are distinguished by special artistic properties, are suitable.

Structural Plaster Features

To the structural and textured plasters, particles and fibers of various fractions are added to the composition. Depending on the filler, the result is the effect:

- fur coats (“Lamb”) with a granular or fibrous surface,

- terrazite (imitation of natural stone with a rough surface).

When using additional tools, such as grinding machines, special sponges, textured rollers, you can achieve an enhancement of the effect or modify it according to the design idea.

Features of Venetian plasters

Unlike textured blends, this variety has a uniform structure and an almost perfectly smooth finish. Using such plasters you can imitate such rocks as marble, onyx, etc.

Working with Venetian plaster mixes requires more skills, effort and investment. The mixture is applied to a pre-primed surface (concrete, wood or any other material) in several layers. There can be up to ten layers depending on the desired effect.

After complete drying, the finish layer is covered with wax to give it additional radiance and better surface preservation.

Marseille wax

Another type of textured plaster is the so-called Marseille wax. Its surface at the finish is smooth, but embossed. Due to tinting, the recesses on the surface have a darker shade, and the bulges are light. This effect looks very interesting as an independent decorative element of the interior, and as a background for furniture and textiles.

Marseille wax is most often found in interiors such as provence, country, baroque. Tinting is used in more delicate shades, pink, lavender, dairy.

Simulated bark beetle

The wooden surface, erratically eaten by bark beetles, looks unusual and even authentic for some interior styles. This effect can also be applied on a plastered wall, if you use a granular decorative mixture.

The larger the granules in the composition of the plaster, the larger and more noticeable the bark beetle furrows will be. Usually, average grooves are used for residential premises, but certain design decisions allow for very small “scratches” and large grooves.

When applying such a mixture, it is important that the thickness of the layer is equal to the size of the granules. If the layer turns out smaller, the particles will be outside and will soon crumble, and too thick a layer will prevent the granules from scratching the pattern.

You can “scratch” a surface both from top to bottom and horizontally, depending on the idea for a particular interior.

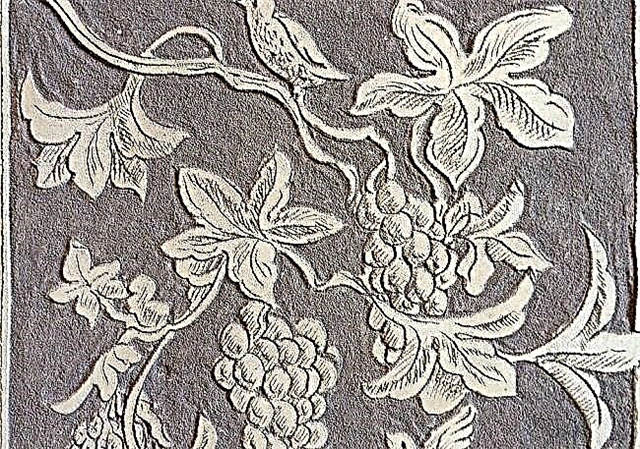

Graffiti technique for decorative plaster

Sgraffito is a technique of applying a plaster mixture in two or more layers with further cutting certain patterns on them. As a rule, the layers differ in color to obtain a contrasting pattern.

The essence of the technique is that the first layer is applied plaster of the color that should be on the patterns. After drying with a second layer, a mixture of a different color is applied, and before it dries, it is removed with a special tool strictly in those places where the pattern is conceived.

To create such a panel on the wall, certain skills or the help of a specialist will be required. But the result is definitely worth it, because the decorative properties of such a wall increase several times due to texture, patterns and the use of several color shades.

Craquelure plaster mixes

The effect of aged, cracked walls has long been gaining popularity in modern interiors. It can be applied both to the classic retro style, country, and to the loft, modern and even eclecticism. The main thing here is to correctly combine the primary color and the colors of the “cracks”.

For example, cracks may be darker in color, and the wall may have a light “fashionable” color. This will create a nostalgic effect of peeping antiquity from under the modern interior shell. You can enhance this technique with various vintage accessories and antique items.

It looks interesting combination of bright (black and white colors can also be considered bright) plain walls and golden or silver cracks. Such walls will look good both in ultramodern and in classically luxurious interiors.

The effect of craquelure is achieved by applying the desired color of acrylic paint to the wall, and after drying it - a special plaster mixture. Some compounds dry out and crack themselves, others need to be heated with a construction hairdryer.

Wet Silk Imitation

Plaster mixes with pearlescent additives in the composition create an amazing effect on the walls. The surface takes on different shades depending on the lighting and viewing angle, the gentle overflows are dim and unobtrusive, but have a high decorative effect.

Most often, such plasters are used in bedrooms and living rooms in combination with a large number of textiles and upholstered furniture.

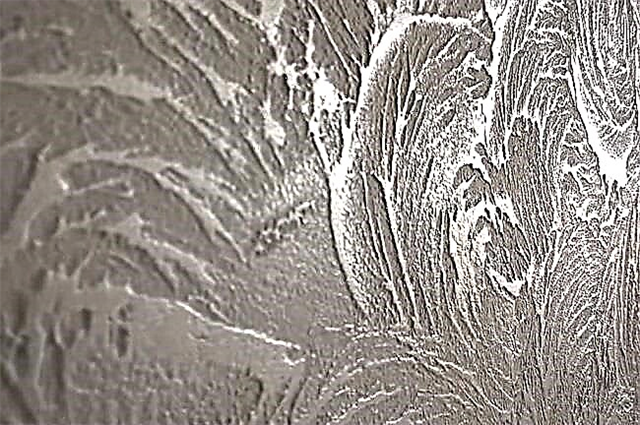

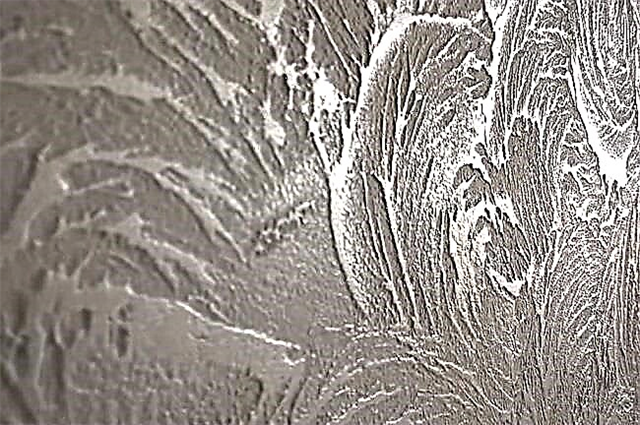

Various simulations using special tools

In general, any of the above mixtures can be further decorated using special tools at the application stage.

To do this, you will need:

- textured rollers (patterns are very different, floral and geometric, with randomly located recesses and symmetrical waves),

- serrated spatulas with jagged edges

- improvised tools and materials (sponges, hard brushes, paper, bags, etc.).

It is quite easy to work with textured rollers, you just need to choose a suitable pattern and follow the basic recommendations when applying the mixture.

Using spatulas with carved edges, you can create waves (large and small), circular patterns, even stripes. In the video on the use of such tools, you can see which movements create certain patterns.

Additional texture can be given with the help of various improvised items. For example, a crumpled plastic bag wrapped around a roller will leave chaotic irregularities on the surface of the plaster. Using a sponge, the surface can be roughened, and stripes and scratches can be created with a metal brush.

How to choose decorative plaster?

The first thing you need to pay attention to is the composition of the mixture. For interior work, you need to choose plaster only from high-quality, environmentally friendly materials. In order not to miscalculate, it is worth starting a search among famous brands:

The second aspect is the purpose of the mixture for a particular room. For example, for the bathroom you need to choose a waterproof latex-based plaster, for the kitchen this option will also be preferable. But for bedrooms, living rooms, children’s, you can choose a mixture based on other materials.

If you make repairs yourself and do not have much experience in plastering, it is better to pay attention to ready-made mixtures. They do not have to be bred according to verified proportions, which will greatly simplify the task for the master and speed up the process.

High price does not always mean excellent quality. Most often, various additional properties of the plaster just add value to it - for example, easy washing of the surface or fire resistance. Some of these characteristics will be useless in a particular case, and you can not overpay for them.

Recommendations for the care of decorative plaster

As with any material, decorative plaster needs some care so that the surface of the walls remains intact and beautiful for as long as possible.

In this matter, recommendations can also be divided by type of mixture:

- Plasters with imitation of velveteen, velvet, silk, etc., applied to the walls with a sufficiently thin layer, must be cleaned as carefully as possible. To do this, a soft cloth soaked in warm water is suitable.

The main thing is not to forget that solvent-based products cannot be used for any type of plaster! This can not only spoil the color of the surface, but also destroy the structure of the material.

What is decorative plaster?

Decorative plaster is an elastic thin-layer coating, its texture is provided by fillers, applied tools and application technologies. This material gives a special charm to the interior, presents a modern design for the decoration of the walls of the premises. With its help, architectural elements of arches and buildings are decorated.

What is the difference between decorative plaster and ordinary plaster? First of all, the fact that it is the final stage of wall decoration. The variation of its textures, colors and application techniques is quite wide. Then, as a gypsum mortar, it can be used only as a basis for decorative coatings, as a simple way to align walls.

According to some characteristics, decorative plaster is similar to liquid wallpaper. However, the latter are less universal and have a variety of colors only. They can be easily damaged, while decorative plaster is distinguished by high strength. Liquid wallpaper is easier to apply and dismantle, but they are inferior in terms of scope.

Advantages and disadvantages of decorative plaster

The advantages of decorative plaster include:

- A variety of application options on the facade of the house and indoors.

- Undemanding to the basis. Suitable not only for a brick or concrete wall, but also for a surface made of metal and wood.

- Seamlessness and disguise. Seamless coatings from this type of material mask the imperfections of the ceiling and walls.

- Security. Decorative plaster is a non-toxic, environmentally friendly, antistatic material.

- Durability, strength and reliability. The service life is not less than that of tiles and artificial finishing materials.

- Protects walls from mold and mildew.

- Affordable price.

The disadvantages of this finish include high consumption per 1 sq.m. surfaces and the complexity of dismantling.

Composition of decorative plaster

Two main requirements for this finishing material are distinguished:

- preservation of plasticity for a certain time,

- strength after solidification.

Decorative plaster performs its tasks due to its composition. As a binder, both lime and synthetic materials are used: acrylic, epoxy resins, polyurethane, etc. They provide the plasticity of the solution, providing time for decoration.

Decorative properties of the plaster mortar provide fillers. It can be: wood and cotton fibers, a variety of pigments and plasticizers, marble dust. Small items can be added: pieces of quartz, mica, gold or silver threads, marble chips.

On sale, the material appears in the form of ready-made solutions or dry powder mixtures. For internal work, as a rule, use an aqueous solvent for mixtures, for external work - non-aqueous.

Types of decorative plasters

The classification of this material can be in several ways:

Based on the composition:

- silicate

- polymer

- silicone

- based on minerals (cement, lime).

By area of use:

- for front works,

- for interior finishes,

- universal.

More often use plasters for internal work. However, facade coatings have excellent protective qualities, water-repellent properties. For example, facade plaster bark beetle Emo San Marco, the manufacture of which is carried out on an acrylic silicone base with the addition of components: marble chips, quartz powder.

According to the properties of the outer layer:

- textured (embossed),

- smooth, imitating a certain effect,

- venetian decorative plaster,

- flock,

- multicolor

- protective and glazing.

For those who prefer quality, the main selection criterion is the brand. One of the most popular manufacturers is the Italian company San Marco, which produces high-quality decorative plasters of various types. Some of them are:

Textured stucco San Marco

Intonachino Minerale (Intonachino Minerale) - mineral plaster, made on the basis of lime, has the addition of sand of different fractions. Suitable for creating textures such as chopped stone, a world map with subsequent glaze.

Tamstucco (Tamstucco) - pasty plaster with a base of vinyl polymer. With its help, you can create many different decorative reliefs. It has good adhesion with synthetic, mineral and wood substrates.

Rilievo (Rilievo) - based on this plaster acrylic polymer. The composition has a fibrous filler, which allows you to create a large relief surface. It can be applied on non-plastered substrates. The material is not tinted, so paints are applied on top, for example: Perlaceo, Cadoro, Velature.

Marmo Antico (Marmo Antico) - mineral plaster, made on the basis of a modified lime, which added calibrated marble granules. Travertine textures, a world map, etc. are made from it.

Wall Stucco is a creamy plastic plaster based on vinyl polymer. Plastic features of the material allow it to be applied to any surface, including wood and old decorative coatings.

Venetian stucco San Marco

Canalgrande (Canalgrande) - a thick synthetic plaster with a filler simulating the effect of unpolished granite. It has high strength. The material is tinted in various colors. Granite plaster shows a natural aesthetic appearance in that the crystals included in the composition do not stain and shimmer in the light.

Marmorino Classico (Marmorino Classico) - a thick coating with calibrated marble chips. An ideal material for coating in the form of a “world map” with further decoration with colored varnish or wet silk.

The assortment of San Marco still has many Venetian plasters and plasters of other types with their own characteristics, which can be used to obtain the intended result. San Marco decorative Roxidan stucco, imitating a metallic patina, is gaining popularity. Whatever decorative plaster you choose, the main thing is not to forget about the quality of the material. San Marco plasters are highly environmentally friendly, materials are hypoallergenic, do not contain harmful substances and volatile organic compounds.

Some nuances of applying decorative plasters

Some features of working with this material can be noted:

- In most cases, the plaster is not painted: a colorless textured version is used, or pigmented dye is added during cooking.

- Using this material, you can make the effect of not only a stone or wooden surface, but also many others. For example, to imitate suede, metal coating, apply patterns using stencils, etc.

Unusual color solutions master receives, using a wash in several colors.

Before starting work, you need to clean the surface, remove old wallpaper, paints, remove nails, other objects, wash away building dust and dirt, everything that can interfere with the application of a new coating. Then an acrylic primer is applied to a clean, dry wall, preferably with an antiseptic. The plaster solution can be applied to a completely dried soil layer.

Photo and video clips on the goods will help to understand in more detail how to properly cover the surface, how to paint.

The most fashionable decorative plasters in 2018

The trends in the interior of 2018 do not put in a strict framework for designers. A trend such as minimalism has returned to fashion, the basic rule of which is the limited number, simplicity and functionality of each thing. To create this style, it is worth choosing materials of natural, rough texture (concrete, wood, brick). You can get the desired effects in the design with the help of San Marco decorative plaster. For example, the Venetian stucco of San Marco in the style of minimalism can reproduce all kinds of surface variations, including:

- matte

- classic glossy

- Roman plaster, etc.

The fashionable design of the kitchen involves the use of sunny, bright colors. To transform the whole room, it is enough to make a stylish wall in a green, blue or red shade. Finishing materials of the Italian manufacturer will be able to make a surface that can be washed in case of contamination, while the colors remain the same expressive.

This year, the main material was marble, and therefore materials that mimic it. With their help, designers create "marble rooms".

Non-ferrous metal is the next trend material. It is also imitated by San Marco decorative coatings, for example, forma textured stucco with the effect of aged metal Forma creates a surface relief, and Roxidan from San Marco is used as a glaze protective layer, giving, directly, the rust effect itself.

Our store offers a large assortment of matte plaster, as well as all the latest innovations. You can always quickly pick up and buy certified products from the manufacturer. Here you can find technical specifications, a description of the material and reviews about it, find out the current price. You can place an order on the website, in the salon, as well as by phone.

Varieties and differences of decorative plasters:

The shops sell different types of decorative plasters for interior wall decoration. They differ in composition, namely, the connecting element. By consistency, the products are divided into dry powder, which must first be diluted with water, and a ready-made paste-like mixture. It can be applied immediately to the surface. Regardless of the variety of the product, it has several advantages compared to other finishing coatings.

Material Features

There are several reasons why it is beneficial to use this material in any room, including a bathroom and a balcony.

- Additional soundproofing. Of course, noise cannot be completely removed, but you will create an additional barrier.

- Resistance to moisture and temperature changes.

- Aligning bumps on the wall.

- Long service life.

- Decorativeness. Using simple tools, you can create a variety of effects, even imitation stone.

- Possibility of wet cleaning.

- It does not absorb odors.

- And breathable.

Applying the interior finish without any problems is carried out on virtually any surface. The material fits well on concrete, drywall, brick, wood, stone.

Acrylic

Universal, flexible mixture based on acrylic resin. It can be painted in any color with the help of pigment paste. Products are sold in finished condition, packed in buckets. It has the following properties.

- It dries quickly.

- Suitable for rooms with high humidity and temperature extremes.

- Durable - service life up to 15 years.

- The finished surface is easy to clean.

And also the mixture has three drawbacks. It will easily burn, may crack under the influence of ultraviolet radiation and has poor vapor permeability.

Mineral

The composition of this decorative plaster includes lime, cement, particles of minerals, stone chips and clay. Below are a few features.

- The coating is most in demand, as it is inexpensive and easy to apply.

- Sold as a dry powder.

- The finished layer is not afraid of moisture and frost, is resistant to abrasion and is the most environmentally friendly of all.

- Before work, the wall must be well primed and putty all the bumps.

Three more advantages: fire safety, ease of care, breathability. Disadvantages: fragility (maximum period - 10 years), the possibility of staining only after complete drying, and low elasticity.

History of occurrence

In the world, gypsum plaster began to be used about three thousand years BC. e., plaster on the territory of the USSR was used as far back as the VI century BC. e. Multi-colored or, as they call it now, “decorative” plaster was used for buildings and temples built on the Taman Peninsula.

Probably decorative stucco originated in ancient Greece. In part, examples of the first use of the material may be considered some examples of cave paintings. Not all drawings of cave people are made directly on the stone, some are based on a solution of clay and sand, which leveled the surface and ensured a convenient deposition of paint. This technique was used later, for example, to create frescoes, later transformed into one of the decoration methods.

In ancient Egypt, a painted textured coating was used to design the interior of the tombs. The seams between the blocks were filled with chalk composition with the addition of organic glue, polished, decorated with drawings, murals or counter-relief (slotted relief). In Mesopotamia, Ancient India and China, lime, clay and gypsum mortars were widely used to give more decorativeness to rough brick and stone walls. Ancient masters experimented with ingredients: added volcanic dust, wine, natural dyes. In India there was a “Pink City”, the walls of which were covered with stucco with blood as a pigment.

The ancient Greek philosopher Theofrast was the first to describe recipes and technology for applying decorative plaster. Marble dust was added to the composition, and the surface after application imitated a cut of natural stone, at the same time, due to stone flour, it had greater strength. The new material helped to significantly reduce the load on the building structure, as it was easier to clad in natural stone.

The art of ancient Rome was eclectic, and eclecticism loves to imitate one material with another. Marble plaster coming from Greece was actively used to decorate facades, interiors, and patios. The decoration reproduced the pattern not only of the marble surface, but also of other finishing materials. Unlike stone slabs, she was not afraid of earthquakes - a frequent occurrence in that region. With the advent of concrete, plaster acquired a new pattern: larger particles were added, which allowed creating an expressive relief. Today, the coating has transformed into travertine and other structural plasters.

After the fall of the Roman Empire, its culture disappears, and with it the desire for “embellishment” and decorativeness. The interiors of the European Middle Ages are ascetic, minimalistic, gloomy. Plaster becomes a technical material: goes to putty gaps in the masonry and log houses, covering the filling of half-timbered walls. The most decorative use is similar to the Egyptian: substrate for painting. The revised technology of frescoes (painted with tempera paints on raw plaster) has found application in the modern decoration of walls and facades.

During the Renaissance, art received a new flourishing, samples of ancient Greek and Roman art, including architecture, became available, interest in them was growing. In the XV century, sgraffito technique appears and spreads. Colored plaster is applied in thin (2-5 mm) layers, while the color scheme can differ in layers both slightly and have a sharp contrast. Then the picture is scratched, fragments of the coating are removed to the desired depth, thus creating a colored relief pattern. During the Late Renaissance (XIV century), the architect Andrea Palladio studied the ancient Roman decorative plaster, experimented with the recipe, and later developed the technology of imitation of natural stone, which was widely used in Venice and became known as “Venetian plaster”.

From there, the application technique, constantly evolving, falls into Europe, where it is actively used in the decoration of palaces and mansions in the Baroque, Rococo, and Classicism styles. To this day, you can see the interiors of that time, decorated with high-quality imitation of natural stone finishes (marble, jasper, malachite, onyx, amber), wood paneling.

Modern decorative plaster has incorporated all kinds of historical, national application methods and decoration methods. This is a whole class of materials that allows you to create a variety of appearance, performance and finish coatings.

Kinds

Decorative plasters are divided into the following types:

- Colored plaster - ideal for decorating interior walls, door and window openings.

- Stone plaster - resembles masonry made of natural stone.

- Venetian plaster - in its appearance resembles real marble.

- Sgraffito - a type of plaster, which received this name due to the features of the application.

- Terrazitic plaster - suitable for interior walls and facades.

- Silk plaster - designed for interior use. Non-combustible, does not accumulate static electricity. The material consists of natural or synthetic fibers, mineral fillers and various decorative additives. It is applied with a plastic spatula to surfaces plastered and coated with a primer or oil paint. It has various colors and textures, has no smell, when applied, a seamless coating is obtained, the material is elastic and does not crack when the walls “shrink”. The main disadvantage is poor moisture resistance, but when treated with moisture-proof varnish, it can also be used in rooms with high humidity (kitchen, bathroom, etc.).

Classification

There are many options for classifying materials.

Depending on the type of binder, there may be:

A mixture on a mineral binder (lime, cement) is environmentally friendly and economical. It is sold in the form of a powder, which is diluted in the right proportion with water before application. The color scheme is not wide, often light colors. The coating is gaining strength over time, it is permissible to use in wet rooms, but is afraid of vibration. Differs in resistance to ultraviolet.

Acrylic binder gives the plasticity of the mixture, which is sold ready to apply. Some compositions are allowed to be painted in bulk with pastes, tinted compositions are found. The mixture is elastic, which allows to achieve various decorative effects. The material is not afraid of water and vibration after drying, sudden changes in temperature, frost-resistant. As a result of exposure to UV rays, it can change color and become covered with cracks. However, the surface is not vapor permeable, therefore it is better to use it not on the entire plane of the walls of the room, but locally, for decorative accents.

Silicone-based decorative plaster is also sold as a finished mixture with a rich color scheme. After drying, it is characterized by high strength, is not afraid of even shock, does not fade in the sun, is moisture and frost resistant, tolerant to temperature extremes. But the use of silicone in the base leads to a rise in the cost of the material.

Silicate is made on the basis of liquid glass. Form of sale: dry mix and finished pasta. Of decorative plasters, the highest indicators of resistance to mechanical damage in mixtures based on silicates. However, the coating is cracked by vibration. It is not afraid of water, ultraviolet radiation, fire, dirt, and prevents mold.But it has a poor range, does not allow tinting, it is better to use it in the design of facades because of the possibility of releasing toxic compounds.

There are mixtures on a combined binder. So, for example, acrylic-silicone combine the advantages of both types, while compensating for the disadvantages: elastic, resistant to mechanical damage and ultraviolet rays, moisture-proof and vapor-permeable.

According to the size of the filler, the plasters are divided into:

- fine texture

- fine-grained,

- secondary,

- coarse.

The main filler is stone chips, polymer granules of various shapes or acrylic "chips". The appearance of the surface as a result depends on their size. It can be a smooth, polishable surface, or grainy, loose, or even resembling porous sandstone.

Depending on the type of surface obtained, they are divided into:

Structural, as the name implies, has the same characteristics throughout the thickness of the coating. This is usually a ready-to-use dense, granular mixture tinted in bulk. It is applied in a layer of up to 1 cm, then a deep relief is created on the surface using spatulas and textured rollers.

The medium and coarse structural plaster includes mosaic: a mixture of pebbles of different colors on an acrylic binder. Mixtures with a filler are made not of stone chips, but of polymer granules. It is sold in the form of ready-made pasta of a certain range, some manufacturers offer a composition selection service that allows you to choose the shade you need. They do not require further coloring, they are highly decorative and vandal resistant.

Textured plaster contains small fillers, which allows you to simulate various textures. These are dry mixes, or ready-made pastes, characterized by homogeneity, elasticity. They are painted in bulk, or after drying. A less dense consistency and high elasticity allow you to apply thin (about 1-2 mm) layers, use a variety of tools (not only spatulas and rollers, but also sponges, brushes, stencils, stamps), all kinds of techniques for imitating surfaces. You can create the illusion of a wooden surface, genuine leather, or suede, waves, concrete, textiles, crumpled paper, etc. After application, it requires protection with waxes or varnishes.

Venetian plaster imitates a cut of a natural stone. The fine-texture mixture is supplied both in finished form and in powder form, and is dyed in bulk. The finest layers, depending on the desired effect, are applied in one direction or randomly. As a result of applying translucent layers (up to 9), a unique pattern appears. An additional drawing of the veins is possible. With its help, you can simulate metal. The finished coating is glossy and polished, and then waxed for protection and greater smoothness.

Application Methods

There are various application techniques, the choice depends on the decoration idea.

The relief is created using:

- trowel

- straight and uneven trowels,

- mastekhin,

- textured and conventional rollers with foam, fur coats,

- stencils

- sponges

- brushes of different stiffness,

- stamps

- materials at hand: e.g. paper, polyethylene, textured leaves,

- hand sculpting.

Depending on the chosen tool and technique, the final coating has a small repeating pattern, or acts as an art object and an emphasis in the interior.

Decoration Methods

The composition is tinted in bulk or stained after complete stabilization. To paint the finished coating, paints are used (for silicate plaster - silicate, in other cases, water-dispersion). The color additionally emphasizes the relief, which increases the decorative effect.

Further decoration is:

- applying glazing compositions

- applying compositions giving the surface texture (craquelure, fluorescence, imitation of rough stone, wet surface),

- gold leaf or silver leaf coating,

- partial toning of the protruding parts.

If the composition and operating conditions require it, at the end of the work the surface is covered with a protective varnish or wax.

The exposed surface of the plaster lends itself to abrasion and scratches. Thin relief protrusions can be chipped off under mechanical action. Wall varnish creates a strong transparent protective film that hugs the protrusions of the texture, protects the plaster from external influences and gives the surface a matte or mirror finish.

Notes

- ↑Ekelchik Moses Solomonovich.A brief reference to the manufacturer of construction works (Russian). - Gosstroyizdat, 1961 .-- S. 332. - 690 p.

- ↑ 12Russian S.F.S.R. Ministry of Education, Soviet Union. Ministry of Education.School and production (Russian). - M.: Pedagogy, 1982.- S. 48.

- ↑ Classical and new technologies for finishing coatings, 2007.

Normative literature

- GOST R 55818-2018 // Decorative plaster compositions on a polymer basis for facade heat-insulating composite systems with external plaster layers. Specifications ..

- GOST R 54358-2017 // Decorative stucco compositions on a cement binder for facade heat-insulating composite systems with external stucco layers. Technical conditions