Before starting any repair, you need to correctly select all the necessary finishing materials. For each type of surface, rooms have their own types, which affect the final quality. So, moisture-resistant putty is suitable for baths, as well as for work in other damp areas. Its use makes it possible to obtain a truly resistant coating, which will not be subject to destruction and the appearance of various fungi and mold.

Necessary material properties

It does not matter why the surface is prepared in the bathroom, for painting or tile. In any case, the putty should have the following properties:

- Possess increased resistance to moisture, be waterproof. That is, even after many years, the applied layer should not be destroyed.

- The second property also implies the second. Namely - durability. So, the service life should be several tens of years.

- There is another negative factor that constantly affects coatings - temperature changes. Therefore, it is necessary that the putty calmly withstand them.

What you need to get in the end, when the moisture-proof mixture takes its place? It should be a very strong and resistant layer. And if you apply a tile as a protective and decorative coating, then it should hold on like a glove.

Moisture resistant putty

Moisture resistant putty

On a note! The above properties are basic, but you must always proceed from real conditions that require additional criteria. So, if it is supposed to carry out painting, then you need to carefully approach the choice of finely dispersed mixtures.

What are the bathroom mixes?

Now on the market there are many different putties that vary in composition and are suitable for wet rooms. It is the presence of different components that determines what qualities the mixture will have.

Based on the necessary properties, two types of materials can be distinguished:

| View | The properties |

|---|---|

| Cement based waterproof mix |

• sand - very fine fraction,

• marble chips,

• clinker chips,

• hardener,

• plasticizer,

• modulator.

All this makes it possible to use putty even outside the building.

However, there is one significant drawback that does not apply to quality. Namely - high cost.

Attention! Plaster putties should not be used for work in damp rooms. Many manufacturers mislead the consumer, indicating the word “waterproof (moisture resistant)” on the packaging. You need to understand that this is a simple fraud. Even if a lot of synthetic additives are added to gypsum, then he will not be able to acquire the necessary qualities.

Preparatory stage

- Completely remove the previously applied coating. Expand cracks that will be repaired first.

- Protruding objects - screws, mortgages, knock down with a hand tool.

- With the help of rags dipped in water, dust and dirt are erased.

Soapy solution and turpentine treat fatty areas.

- All damaged areas are completely cleaned.

- If there are traces of the appearance of such phenomena, then they are additionally burned with a blowtorch.

- Antiseptics pass all surfaces well, attention should be paid to joints and seams.

After drying, proceed to another stage.

- A solution with deep penetration is selected. It is better to give preference to a primer, which includes an antiseptic in its composition.

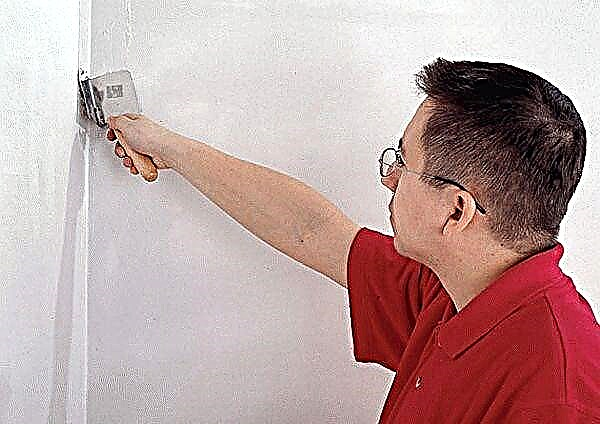

- Applying a primer does not require special skills, you can use a spray gun.

Before proceeding with the main actions, you should wait for the complete drying of the applied layer.

Advice! It happens that on the walls or ceiling, large cracks or holes between the seams are found. They are sealed with cement plaster. Although you can simplify this work a little, for this they take mounting foam. It patches large damage well and does not require much application effort.

Puttying

Putty for the bathroom must necessarily contain an inscription on the package - suitable for wet rooms, and also belong to one of the types that were given above. Thus, we can say that the main condition will be achieved a priori. Namely - the mixture will have the necessary qualities. But now another problem arises, it needs to be applied correctly.

It is especially difficult when painting surfaces is intended. The fact is that paint immediately detects and highlights all existing defects.

Determine the required number of layers. If the work is done on already applied plaster, then you can limit yourself to the finish mixture. When there are significant irregularities that require the application of a solution with a thickness of one centimeter or more, they resort to starting putties.

Starting putty - used in the presence of significant irregularities, cracks and drops

Starting putty - used in the presence of significant irregularities, cracks and drops

Often use dry cement putty, it must be prepared:

- The right amount of composition is poured into the container, little by little water is added, constantly mixing the mixer with a drill and nozzle.

- It is required to obtain a pasty consistency, which is left for 10 minutes. This is to ensure that all additives are completely dissolved. After this stirring is repeated.

Breeding dry putty

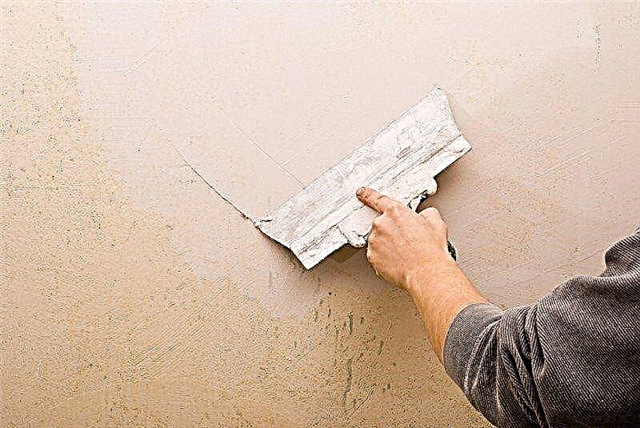

Breeding dry puttyThe hardest part begins - applying the mixture to the surface. Although if you practice a little, it turns out that everything is not as scary as it might seem at first glance.

For work, two main tools are used: a medium and a large spatula, they keep a small one in reserve, it will be needed for puttying in hard-to-reach places.

Start of puttying

Start of puttying

- In large areas, the following technique is used: the solution is sprayed from below, and then smoothed out with a rule.

- When this is not possible, they do so: with a middle spatula, apply the mixture to a large one, which they work on the surface.

- Angles are formed with a special angular tool.

Alignment of internal angles with a trowel

Alignment of internal angles with a trowelWith the help of such simple rules, it is possible to apply starting and finishing compositions in any wet rooms.

After complete drying, the surface is polished. If you want to get a perfectly smooth, almost mirror layer, then use the gloss method.

Surface grinding - finishing stage of puttying

Surface grinding - finishing stage of puttying

Why is moisture resistant putty necessary?

Often the preparation of the surface for finishing is associated with the alignment of uneven areas and the application of a layer of putty. But it is important to choose the purpose and type of mixture depending on the room. Not every putty is suitable for wet rooms. If it is selected incorrectly, the entire repair will not live up to expectations. Therefore, a moisture-resistant putty for the bath must be used.

It is applied to all surfaces that are exposed to water and moisture in various forms. So, it can be a direct hit of water or moisture on the surface, the formation of vapors or condensate. If you do not treat the walls and ceiling with such a composition, the paint will peel off very quickly, and all repairs will not justify the investments and everything will have to be redone.

Putty for wet rooms should be used not only in the bathroom and the bathroom. It is ideal for the kitchen, pool and bath. The cost of such material is slightly more than usual, but it pays off almost instantly after the repair is completed. Mold will not appear under the ceramic tiles, and the paint will last a very long time and will not lose its original color. The surface will remain perfectly flat, which is important for subsequent decorative finishes.

Main types

Waterproof putty for the bathroom is presented in several ways. Each mixture has its own advantages, which are necessary for certain conditions. To choose the right option, you need to familiarize yourself with the main options for putty:

- Cement. This is a material with high resistance to moisture. This composition is ideal for applying to the walls and ceiling in the bathroom of a house or apartment. Cement putty is inexpensive, which makes it affordable for most buyers. Of the negative aspects, a grayish tint and granular structure can be distinguished. It should not be used in combination with white paint or other light colors.

- Gypsum This putty for the bathroom stands out in a pleasant light shade. The mixture dries quickly and perfectly prepares the surface for painting with pastel colors. Putty lays evenly, which facilitates subsequent finishing. But this material is used only for indoor use. It is not suitable for working with facades. This is due to the fact that gypsum does not tolerate temperature extremes.

- Polymer. This finishing mix is an advanced development. It consists of high-tech particles, and the process is high-tech particles, and the polymerization process is carried out in contact with air. Moisture-resistant putty remains plastic for a long time, so you can work with it slowly. But with similar formulations, a respirator is required.

- Oil and glue. This material is a powder mixture requiring dilution. Such a putty layer is ideal in utility rooms that do not need high-quality repairs.

On the video: how to plaster the walls in the bathroom.

The properties

Putty of the walls in the bathroom and other wet rooms is carried out for subsequent painting or surface treatment with ceramic tiles. Regardless of the decorative layer, putty should have the following properties:

- high resistance to moisture, which preserves putty even after tens of years,

- resistance to temperature changes that are characteristic of the bathroom and kitchen,

- environmental friendliness, since the mixture must be safe for human health,

- affordable cost, which is important when applying to a large area.

As a result, you should get a stable and strong layer, which is ideal for the ceiling and walls in the bathroom. It should interact well with tile and coloring composition. If you plan to apply bright or dark paint, you can stay on the cement mixture. If you are looking for a composition for walls for painting, pay attention to the polymer mixture Vetonit.

These properties are basic. In a specific situation, it is necessary to be guided by the most important qualities for the premises.

One of the most versatile is Knauf plaster, which allows you to create any design solutions even in the wettest rooms.

Features of working with moisture-resistant putty

Any putty for a bathroom, pool and other damp rooms gains hardness during the day after application. Quality compounds have increased elasticity. They cover the surface with an even layer and are characterized by good adhesion to the main surface. Knauf plaster with a moisture-resistant effect makes it possible to protect the base well and establish a finish with high decorative qualities.

Cement based mixtures, such as Vetonit, include plasticizing agents and pigment dyes. The result is an optimal putty for the bathroom for painting.

Some compositions can be used in facade works. But they can also be used for processing the internal surfaces of rooms. The Vetonit putty mix intended for front works is successful for use on walls in damp rooms. This is a great solution if you have a mixture after working on the outer surface of the walls. But you can also get a special composition for rooms with high humidity.

A feature of most modern mixtures is the lack of the need to purchase special tools. The compositions are used on the primer layer, which can be applied manually. After that, alignment is carried out, covering all irregularities and minor defects.

Advice! On critical surface areas, it is necessary to apply another layer of the mixture with a moisture-resistant composition. This is important if you are using putty under a tile.

Subtleties of choice

Using putty for a pool or kitchen, you should be careful and act slowly. It is important to study the presented assortment in order to choose a suitable product. Having familiarized yourself with the Knauf positions, study the instructions for using the mixture.

Give preference to one that is distinguished by an acceptable composition for you and the necessary properties. As a result, you get a waterproof surface that is completely protected from moisture. It is worth considering that the waterproof Knauf mixture dries faster than the standard.

Pay attention to the term hydrophobicity. If it is present on the package, the finished mixture must be applied in 2 layers. As a result, the painting will be simple and high-quality, and the coating will remain in its original form for many years. When buying Vetonit plaster, keep in mind that it must match the material being processed.

The coarse sand mixture is suitable for masonry. And if you need to process smooth blocks, give preference to mixtures with fine quartz sand.

Composition and specifications

Putty for bathroom and kitchen has a special composition, which determines its properties. Manufacturers in most cases produce mixtures containing Portland cement. This is crushed clinker and gypsum crumbs. Therefore, it is presented in powder form. In order for the suspension to turn into a hard coating, water must be added. The correct proportion of dry matter and solvent is indicated in the packaging instructions. The main feature of the putty is the fact that when moisture or steam gets on it, it becomes more durable.

Different types of putty during polymerization may acquire a lighter or darker shade. Thanks to Portland cement, putty is used both for interior work with the goal of covering the walls of the bathroom or kitchen, and for facade work.

In addition to the main components that are part of the basic composition, various coloring pigments are added. More expensive fillings are usually white or light gray. Cheap formulations in most cases have a gray or dark shade.This should be taken into account if decorative finishing work is to be done with light-colored materials.

Putty for bathroom and kitchen dries in 24 hours. Compositions for application in atmospheric conditions have the following characteristics:

- elasticity

- increased strength

- accelerated solidification time,

- additional polymerization under the influence of water,

- ability to firmly hold additional materials - tiles, panels, decorative elements,

- good adhesion to the surface of walls and ceilings,

- providing an even and smooth finished layer.

Consumption per 1m2

Before making a purchase, you need to determine how much moisture-resistant putty is needed. The total amount of material depends on such factors:

- surface area on which the mixture will be applied,

- the degree of curvature of the walls and the number of deep cracks,

- coverage ratio

- type of solution.

Each product packaging is accompanied by instructions for use and manufacture of the mixture. The calculation of putty on 1m2 is determined by its type. Therefore, the amount of substance may vary from different manufacturers. The layer thickness is determined by the type of suspension and ranges from 0, 1 to 5 mm. The average dry mass per square meter is one kilogram with a layer thickness of 1 mm.

Attention! When calculating the putty, the full volume of the finished mixture with a margin of 10% must be taken into account.

You can use the help of Internet resources. On special sites on construction topics, developers offer a calculator for calculating the required amount of putty. The indicators are most accurately brought into certain cells, and the program produces the exact result.

Features

Moisture-resistant putty differs from similar mixtures in its properties and composition, which determine the characteristics of the operation of this type of material. They are represented by the following characteristics:

- good moisture resistance

- the absence of destruction during prolonged exposure to water and steam,

- a service life of at least ten years,

- keeping under conditions of temperature fluctuation.

Please note that tiles or other decorative elements are often attached to putty for the bathroom. Therefore, the polymerized solution must retain a certain weight of the additional coating.

Advantages and disadvantages

Thanks to the special composition, the putty has certain advantages over other solutions. Positive differences are presented:

- maintaining high strength when exposed to moisture,

- the presence of additional antibacterial and antifungal components,

- universality when applied indoors and as a facade coating,

- quick setting time.

Almost the only drawback is the coarse-grained structure, which is due to Portland cement, which is part of the composition. However, when used in bathrooms, this is offset by tiles, which are superimposed at the final stage.

Tools

To perform the work, you must take care of the tools in advance that are useful in the repair process. Should be prepared:

- container go bucket for mixing solution

- brushes of various widths for preliminary priming,

- spatula of several sizes,

- the rule

- mixer to prepare a homogeneous mixture,

- emery coated paper of varying degrees of graininess for subsequent sanding,

- protective clothing and mask.

Tips & Tricks

Repair can be entrusted to a specialist or perform it yourself. To do this, you should study the recommendations of experienced masters. When working with moisture-resistant putty for a bath, you need to consider such points.

- A humid environment does not harm the putty, but rather strengthens it even more. Therefore, it is not necessary to include ventilation in addition.

- In the process of preparation during priming and cleaning it is necessary to free the surface from old materials as much as possible.

- If the decorative materials for the final finish are made of light materials, then the putty is also better to choose with a similar shade.

Varieties

Wet rooms are characterized by special operating conditions. Therefore, it is better for them to use moisture resistant putty, where the base component is a cement or polymer base. Such compositions protect the material well from corrosion, adverse effects of bacteria or mold, cracks. The following mixes are offered on the construction market.

- Cement - which is characterized by high resistance to moisture. Putty is suitable for covering walls and ceilings in the bathroom and toilet. The suspension has decent quality properties and is affordable. It is characterized by a large granular structure and a dark shade. Therefore, it is undesirable to combine with light tones of paintwork. The disadvantage is the long filling time of polymerization and significant shrinkage, which requires frequent ventilation of the room.

- Gypsum - the main advantage of the composition is a pleasant light shade, which serves as the base layer of coatings of any color. The uniform structure facilitates the process of applying putty and provides a smooth coating. However, the composition is less resistant to changes in atmospheric indicators, therefore, is not suitable for external work and is limited for use in bathrooms.

- Polymer - currently one of the most advanced construction developments. Putty contains high-tech substances that freeze when in contact with air. Allows you to create the smoothest white surface. It can be used as a top coat. However, it contains some allergens, therefore, to carry out repair work, it is necessary to use personal protective equipment.

- Oil-glue - a powdery suspension for the preparation of the finished solution. The use of this type of putty is considered by some masters to be an obsolete method. However, affordability and pricing determine its relevance in the construction services market. The mixture dries longer than other types of putty. Therefore, the scope of use is mainly limited to the repair of utility rooms.

- Arkilovoy - which is characterized by high plasticity and environmental safety. Suitable as a universal tool for working outside and inside the house.

- Latex - when using putty, cracks rarely form. However, the mass is sensitive to sunlight and temperature extremes. Therefore, it is better to use it indoors.

Putty is applied in several layers. To create smooth walls and ceilings, it is necessary to use several options for mixtures. Depending on the purpose of application, the compositions are:

- starting - which are applied as a base layer to hide large defects and cracks,

- finishing - serve for the final work, eliminating minor defects,

- universal - can be used to level the surface with the presence of bumps and blockages of any size.

Manufacturers produce waterproof putties for the bathroom of various types, which differ in structure. Such mixtures are presented in form.

- Dry - powdered substances that need to be diluted with water. They are characterized by quick solidification, therefore, experts recommend preparing small volumes of putty and quickly applying the solution,

- Liquid - suspension can be applied immediately after opening the container. Such compositions are convenient to use, do not require additional actions and save time when performing repairs. However, the finished version has a higher cost compared to dry putty.

Mixture preparation

After preparing the surface, putty is chosen. Depending on the nature of the walls and ceilings, the volume of the mixture and the number of layers for application are determined. If the coating is smooth, finishing treatment is allowed. In the presence of defects, the starting and fine-grained mixture is used. An important step in the preparation of putty. Proper mixing is performed as follows:

- pour a small amount of dry powder into the prepared container,

- add water slowly, constantly stirring the mixture manually or using a construction mixer,

- leave the finished solution for several minutes to completely dissolve the particles.

Liquid mixtures are intended for application without prior dissolution.

Application

The process of applying moisture resistant putty involves several stages. It is necessary to carefully prepare for each of them and learn how to carry out such work. Puttying a bathroom or kitchen involves the following steps.

- Preparing the walls and ceiling for repair.

- Conducting the main work.

Proper execution of the first stage provides a long service life of the base coat and other materials. Experienced professionals recommend sticking to such events.

- Surface cleaning. It consists in removing old material from walls and ceilings. They clean cracks and crevices and expand them under the finished solution. If there are screws, nails or other parts on the wall, they are removed with special tools. After that, the surface is washed with a damp rag, remove dirt and dust. Grease stains are removed with turpentine and a washing solution.

- Treatment with antibacterial and antifungal agents. In conditions of high humidity and high temperature, pathogenic flora quickly develops on the walls. Therefore, it is important not only to remove the affected areas, but also to protect the surface from re-infection. To do this, carefully clean them and burn them with a blowtorch. Then a special antiseptic is applied in several layers.

Important! Particular attention should be paid to inaccessible places, joints and seams.

It is very important that each coat dries well. If the bathroom will be painted, it is important to prepare the walls for painting. In this case, the repair will be of high quality for many years. If there are large cracks on the walls that are difficult to repair with putty, you can close them with foam.

After preparatory work, puttying of the walls is carried out. To do this, they throw it in small portions on the wall and distribute it evenly over the surface using the rule. Cracks and flaws are closed with a mixture and smoothed. In the corners and at the joints they work with a special tool. First they work with the starting solution, then with the finishing solution. Each layer should harden. After polymerization of the putty, the walls and ceilings are polished to a perfectly smooth state.

The use of moisture-resistant putty significantly prolongs the service life of any premises with special operating conditions.

Moisture-resistant putty for a bathroom: application features

Putty, with the help of which the walls in the bathroom are finished, must have certain properties that ensure the quality of its use. Regardless of the further decoration of the walls in the room, putty for the walls in the bathroom should be:

- moisture resistant - ordinary putty, swells under the influence of moisture, exfoliates, deforms and generally collapses, moisture-resistant materials, when exposed to moisture, should become stronger,

- long in operation - the minimum period of operation of putty, after its application to the walls should be twenty years,

- resistant to changes in temperature conditions - since the bathroom is a room with an unstable temperature conditions, putty for walls should easily tolerate these fluctuations, expansion and contraction of the putty when the temperature changes leads to its destruction.

Please note that these criteria are crucial when choosing a putty for wall decoration in the bathroom. Individual additions depend on further wall decoration. So, for example, if after finishing the walls in the bathroom will be painted, then the surface should be perfectly even, which means the putty should fit perfectly on the wall. For walls that are tiled, this criterion is less important.

To decorate the walls in the bathroom, use such variants of compositions having a mineral or polymer base:

1. Cement based putty for the bathroom.

For the manufacture of this composition high-quality Portland cement is used. He, when exposed to moisture, becomes even more durable and strong. The coating, after application to the wall, is additionally wetted with water. The main components of this composition, in addition to cement, are fine sand and clinker chips. In order to improve the ductility of the composition, various additives and fillers are added to it.

2. Acrylic or latex filler compounds based on polymers.

Consists of various mineral and synthetic additives. These compositions are more flexible than cement. It does not shrink, it is easily applied to the wall, distributed on its surface. However, the cost of such putty is an order of magnitude higher than that of a cement analogue.

Some experts use facade putty for wall decoration in the bathroom. However, before buying the composition, make sure that it does not contain harmful or toxic substances.

Gypsum-based mixtures are not recommended for wall decoration in the bathroom in any case, despite the fact that some of these compounds are also labeled with moisture resistance. This type of finish is not able to withstand constant steam and temperature changes in the room.

In response to the question of which putty for the bath is to choose, we definitely recommend staying on an acrylic or latex version of the composition. If the cost of the composition is crucial for you, then purchase a cement-based putty with moisture-resistant characteristics.

Moisture-resistant putty for drywall: choice and characteristic

In relation to the purpose, the putty for drywall is divided into types:

1. Putty finishing moisture resistant - more often sold in finished form, used for the final decoration of walls in the room. After finishing with the help of the finishing composition, the walls are prepared for painting.

2. Moisture-proof leveling putty - used in the initial leveling of the wall, this composition allows you to get rid of the joints between the sheets, holes for fasteners, etc.

3. Universal puttying compounds - allow alignment and final finishing at the same time.

In relation to the composition, moisture-resistant putty in the bathroom happens:

1. Compositions based on gypsum - do not shrink, but differ in poor moisture-resistant characteristics.

2. Cement compositions - have excellent moisture resistance, they are well resistant to mechanical stress, but they give a slight shrinkage. With the help of such compounds, the walls are finished in the bathroom under the tile.

3. Polymer putty mixtures - the best option for perfect wall alignment. Putty has a high plasticity, is well distributed on the wall, leveling it. The only drawback is the high cost, it is fully justified by the operational characteristics of the material.

However, note that before applying any mixture in composition, it is necessary to cover the walls with a primer, which will ensure high-quality adhesion of the wall to the material and perform an antiseptic function.

In relation to readiness for use, moisture-resistant putty for a bath is:

- dry - water will be required to dilute this material, the compositions are less convenient to use, since they require a certain consistency and the use of a mixer for their manufacture, in addition, such mixtures quickly solidify, so they are prepared in small portions,

- finished - the compositions are more expensive, but convenient to apply, before using the composition, mix it well enough, in addition, their shelf life is quite long, over time they do not lose their characteristics.

Putty moisture resistant price and application tool

In the process of filling the walls, it is necessary to prepare in advance the equipment that will be needed during operation. First of all, stock up with spatulas of different sizes, with which you will put a putty on the wall.

If you use a dry composition, then prepare materials for its dilution. A bucket or additional container, water, a drill with a mixer nozzle or a construction mixer.

It is also necessary to pre-select a primer, the type of which is determined by the type of putty used in wall decoration. Putty is applied to the wall with a wide spatula, and on a wide spatula it is applied narrow. If there is more than one square meter of wall area, use the rule to align it.

In order to avoid the appearance of cracks on the walls, a mesh is used in the putty process, which improves the mechanical strength of the composition.

Putty for a bathroom for painting: application features

Putty for a bathroom for painting should have the following operational properties:

- high moisture resistance

- antiseptic properties that prevent the development of fungus and mold in the bathroom,

- minimum porosity

- high adhesion to the base, regardless of moisture and temperature difference.

It is with the help of the polymer composition that it is possible to create the ideal coating for painting the walls in the bathroom. Contacting with air, hard putty is polymerized, differing at the same time with high operational characteristics.

After applying the composition, it is possible to obtain a very smooth surface that does not need additional grinding. Such compounds are sold in finished form and do not need additional dilution with water.

Putties on a polymer basis are:

- acrylic - with their help, both finishing and starting wall decoration is performed, they are characterized by a high level of plasticization, therefore they are able to fill small bumps and eliminate defects, the finished compositions are distinguished by the absence of an unpleasant odor, therefore they are used in rooms for people suffering from allergies, have a high degree of adhesion to concrete or wood surfaces,

- latex composition - allows you to get a perfectly mirror surface, has high adhesion, therefore it is distinguished by universal use on any type of surface, during operation it is not prone to cracking and shedding.

Before applying putty on the walls in the bathroom, it is necessary to prepare the walls. Initially, remove the old coating from them, evaluate the condition and, depending on this, follow these steps. If there is fungus or mold on the walls, they must be disposed of using abrasive compounds. In order to remove the old plaster or putty, use a spatula, sandpaper will help to perform the final cleaning.

If necessary, in the deformation of tiles from the walls, use a punch. After that, you should get rid of dirt and dust in the room. In relation to the main material from which the walls are built, evaluate them for cracks and chips, if necessary, plaster the walls.

Clean the walls with a deep penetration primer to prevent mold and mildew on the wall. We recommend giving preference to an acrylic based primer. With its help, not only will the mechanical strength of the coating improve, but also its resistance to moisture will increase.

Please note that removing the finish to the main part of the wall, you increase the material and physical costs of repairs in the bathroom. Therefore, if the base is of good quality, you should not remove it. In any case, first of all, it is necessary to assess the situation by conducting a visual inspection of the walls.

Old plaster remains on the walls in such cases:

1. They are securely fixed to the wall, has no deformation, swelling, cracks. If tapping the wall, the stucco is firmly held on it, it is not worth replacing it.

2. Remove the decorative coating without damaging the plaster layer. Use a spatula to remove wallpaper or paint. Dismantling tiles is almost always done with damage to the plaster.

If you are sure that during the plastering of the walls all technological nuances were observed, then feel free to leave this layer on the wall.

To putty the walls and ceiling in the bathroom, you need to take care of the installation of beacons, the interval between which is up to half a meter. To do this, use the laser level. The most convex point of the wall will be a guideline for determining the thickness of the putty. If there are cracks on the walls, install the cut-out part of the fiberglass or a special mesh to prevent delamination in their place.

If the ceiling in the room will also be putty, then start work with him. Prepare the composition for work by mixing it thoroughly. Apply putty to the corners with a small trowel and spread it over the surface.

To facilitate the filling process, pre-align with the starting compound, and then apply the finishing mixture.

Puttying the walls begins with the installation of the puttying compound inside the deepest cracks and defects. Level the composition with a spatula and wait for it to dry. Treat the wall with another layer of acrylic primer and continue. Note that the adhesion of the finished putty compound to the wall depends on the quality of the primer. Apply starter compound and level the walls.

After it dries, sand the walls. Using a small trowel, apply the finishing putty, the thickness of which should be minimal. For processing a small room, to putty, use a spatula. Wait for the composition to dry and apply another layer of putty.

Wall drying should be carried out in the most comfortable conditions. Drafts should not be present in the room, and the optimum temperature is about 20 degrees. If the putty has a cement base, then excessive humidity in the room will only strengthen it.

After the putty is dried, the walls are prepared for painting. Note that this process begins a few days after the final alignment of the wall. If you perform this process later, the cement composition acquires high strength, and it will be impossible to sand the walls.

Wear protective clothing, a mask and a respirator before starting work. Since a large amount of dust is released during work, irritating the eyes and respiratory tract. Fix the abrasive mesh to a hand or electric wall alignment tool. The option of replacing the mesh with sandpaper with fine grain.

The plane of the walls is processed using circular motions. In doing so, keep an eye on the workflow. Grinding is carried out until there are no bumps on the wall. To check a wall, use a level or rule. Next, get rid of the dust in the room and primer the walls. The primer improves the strength of the walls and additionally fixes the putty.

Further actions for decorating the walls in the bathroom are related to the implementation of their staining. For these purposes, you should also use compositions with moisture resistant characteristics that tolerate temperature fluctuations well.

Wall preparation and puttying

When processing any surface, it must first be prepared. Before applying Knauf plaster, completely remove the old finish. Pay attention to the need to remove dust, dirt and grease stains. Remove protruding elements such as screws and mortgages. They can be knocked down by improvised tools.

Next is the surface disinfection. To do this, clean all damaged areas. It’s good if you treat the wall with an antiseptic. Then the surface must be primed. This is necessary since the primer provides good adhesion of materials to the surface.

Advice! Often cracks or holes appear between the seams on the ceiling and walls. They must be repaired with cement putty. If this is not done, the future finish will not be of high quality.

At the final stage, putty should be applied. But the packaging should be marked that it is suitable for wet rooms. The surface acquires not only perfect evenness, but also becomes protected from the effects of steam and moisture.

Moisture-resistant composition is ideal for repairs in the kitchen and in the bathroom. This putty is indispensable for finishing the pool. But follow the manufacturer's instructions as accurately as possible.

Thus, the putty has a direct effect on the appearance of the finished surface. It not only creates a perfect coating, but also protects it from moisture and steam. Moisture-resistant putty is an excellent solution for those who plan to repair in the bathroom or in the kitchen. It is indispensable in the decoration of pools. The main thing is to follow the sequence of actions proposed by the manufacturer.

Benefits

Bathrooms often have a high level of humidity. That is why the choice of putty plays a big role for finishing work.

Moisture-resistant putty differs from the usual one in that when exposed to dampness it will not lose strength characteristics, unlike its other varieties.

This is the most important advantage, because it is because of it that the life time of the internal wall decoration is significantly increased. To paint on the walls and ceiling did not lose its appearance, it is necessary to use such putty. In addition, this type of mixture is unfavorable for the reproduction of microorganisms: you can be sure that there will be no mold under the wall tile.

This variety is more expensive than the others, but its choice for wet rooms is the most rational. It is more logical to pay a higher price initially than later to fork out for a new repair.

Preliminary work

The appearance of the walls depends on how well the preparation of the walls for puttying is carried out. Well-crafted walls look neat, they safely absorb all subsequent coatings. For the final painting, it is necessary to perfectly polish the wall.

If you have decided on the choice of mixture for putty, you can start preparing for painting.

Recommendations:

- Inspect surfaces for rot, dirt, or mildew.

- Wash off any dust and dirt from the wall with a rag dampened with water.

- Destroy the old wall covering. You can do this mechanically using a grinder, sandpaper or scraper. An ideal diamond grinding machine. In addition, you can use special substances for dismantling.

- Roughnesses and protrusions on the surface should be removed. Cracks (if any) must first be expanded and then cleaned up.

- If the wall has a large number of grooves, cracks and irregularities, fill them with cement plaster. This will make the wall even and cover up any holes.

- Before puttying it is necessary to dry the surface if it is wet. Clean the mold or fungus with a brush, if any. Walk over with a soldering iron.

- The joints and seams of the room are more likely than other zones to multiply microorganisms, so you should pay more attention to them when treating the walls with an antiseptic.

- Primer the walls. This will fix the surface and fill all cracks. Also, the primer has an antibacterial effect. It is very simple to apply a primer; you can do this with a spray gun.

- Large cracks and holes can be fixed with foam. The use of foam does not require special skills, it will not be difficult.

Puttying

The packaging of the putty mortar should contain information that the material is suitable for wet rooms. In addition, the mixture should belong to the above varieties. If all the conditions are met, you can begin to putty itself. The following is an algorithm.

If there are large irregularities on the wall that need to be filled with a layer of the mixture with a thickness of one centimeter or more, proceed to the initial putty. If the result only needs to be fixed, then only the finish will be needed.

Solution preparation

Most often, the consumer's choice falls on dry putty. In order to start using it, you must first prepare it accordingly.

Pour the required amount of Axton solution into a bucket or any other container., then add a little water. At this time, do not forget to stir the mass with a drill with a mixer tip. Leave the solution for 10 minutes. During this time, all additives will finally dissolve, forming a paste-like consistency. After this, it is necessary to mix the resulting substance again.

It should be remembered that you do not need to prepare a large amount of solution at a time.

During the time you work with the wall, it will harden and will be unusable. So you should create the material in small portions.

Preparation for painting

When the putty is dry, you can start applying the paint to the walls. It is necessary to start this stage no later than 1-2 days after adjusting the wall, otherwise the substance with which the surface is coated will become too strong and unsuitable for grinding. In order to start staining, you need to prepare for the procedure, namely, wear a respirator and a special suit. Dust, particles of paint and sand in large quantities will fill the air and may irritate the upper and lower respiratory tract. The abrasive mesh should be fixed to the tool you selected to adjust the walls.

Instead of mesh, you can use sandpaper.

The walls are treated in a circular motion. Sand the wall until it is perfectly flat. Use the level or rule to evaluate the results.

Ventilate the room from dust, then use a primer. It will make the walls stronger and fix the previously applied base.

Recommendations of specialists

The listed rules will help you successfully cope with the application of moisture-resistant putty:

- reinforce the mesh with a coating to increase its strength,

- solutions should not be applied in very thick layers. A 3 mm thick layer is perfect for successful application,

- the use of artificial drying methods (heat guns, heaters) is not very effective. Drying the mixes too fast can crack the wall,

- pigment can be added to the working solution to match the color of the future external wall covering, for example, paint or wallpaper,

- facade putties are excellent for rooms with a high level of humidity, such as a bathroom, kitchen or a room with a pool,

- work should be in a room with an air temperature of more than 15 degrees,

- sanding for subsequent application of paint requires more diligence than sanding for applying tiles,

- in the bathroom, the best solution is a waterproof coating.The usual types of putty will not last long and will lead to not the most pleasant consequences: a spoiled appearance of the repair and a complete replacement of the finishing layer.

Moisture-resistant putty does not require special skills in handling it. Despite the relatively high price, this material will serve you for many years to several decades. It is important to be able to correctly apply the mixture to the surface of the walls, and then the result of the work will please you and your family.

About which putty is better to choose and for which rooms, see the next video.