Any specialist, having familiarized himself with the design of drywall construction, asks the question - what materials will be required in the manufacture of its frame. Naturally, for a “knowledgeable” person, solving this problem will not be absolutely difficult, but what about a novice home master? We decided to help the craftsmen who will assemble the frame for the first time, having examined in our article the varieties of the profile for drywall and its dimensions.

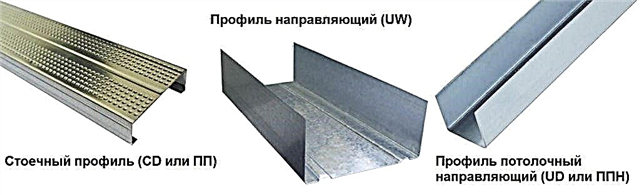

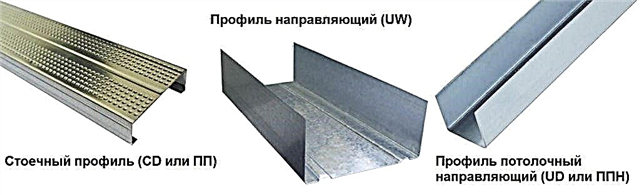

1 - UD, 2 - CD, 3 - CW, 4 - UW

Note that the story only about the types of metal profiles for drywall as one structural element, in our opinion, will not bring much practical benefit. Therefore, we decided to add here a description of the fasteners and related materials used in various methods of mounting the frame.

The main types of profiles for drywall

This, without a doubt, the main structural element, has several varieties, four of which are designed to assemble the frame and are made of thin steel by cold rolling.

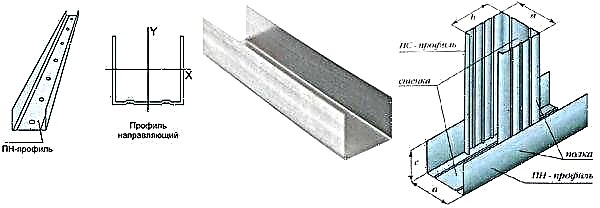

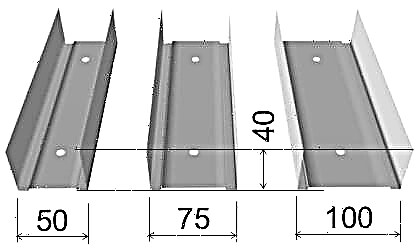

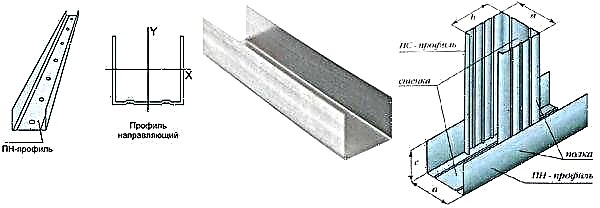

Guide - PN (Eng. UW)

It is used to create partitions and wall decoration, being a guide to which the racks are attached. This wall profile for drywall has the following dimensions (mm):

- length - 3000,

- shelf height (side) - 40,

- the width of the back (base) is 50, 65, 75, or 100.

8 mm holes for dowels were made in the back.

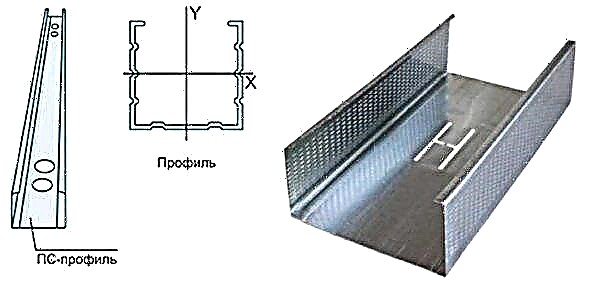

Rack - PS (CW)

It is the main element of the lathing of walls and partitions. Mounted in a guide located around the perimeter of the working area. It differs in that the upper edges of its lateral parts are C-shaped. The most common are the following dimensions of a rack-mount metal profile for drywall (mm):

- length - 3000, 3500, 4000 and 6000,

- shelf height - 50,

- the width of the back (similar to that for PN) is 50, 65, 75 or 100.

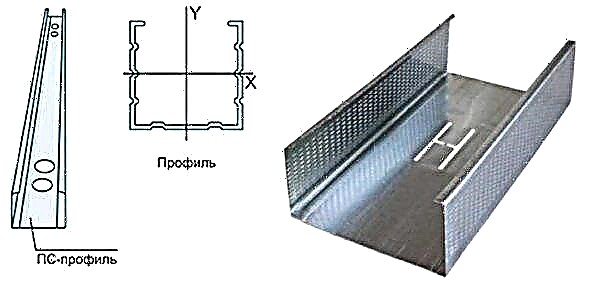

Ceiling - PP (CD)

It is used during installation of ceiling structures. It differs from the rack in that it is attached to the ceiling with the help of special fasteners. The sides and base (“grooves”) are stiffeners that give it extra strength. The standard dimensions of the ceiling profile (mm) are as follows:

- length - 3000,

- shelf height - 27,

- back width - 60.

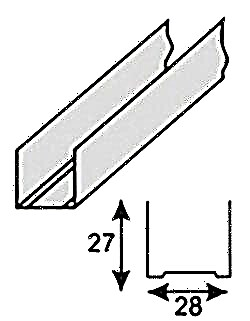

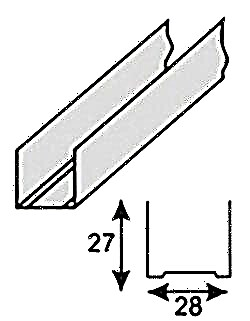

Ceiling guide - PN (UD)

Designed specifically for creating ceiling frames, serves as a guide "base" of the entire structure. Its lateral parts have longitudinal corrugations, which give it the necessary rigidity, and the base is equipped with holes for mounting dowels. The guide ceiling profile for drywall has dimensions (mm):

- length - 3000,

- shelf - 27,

- back - 28 mm.

In addition to these varieties, there are special elements of the frame structure that can strengthen it, provide protection, facilitate decoration or give it a “curved” shape.

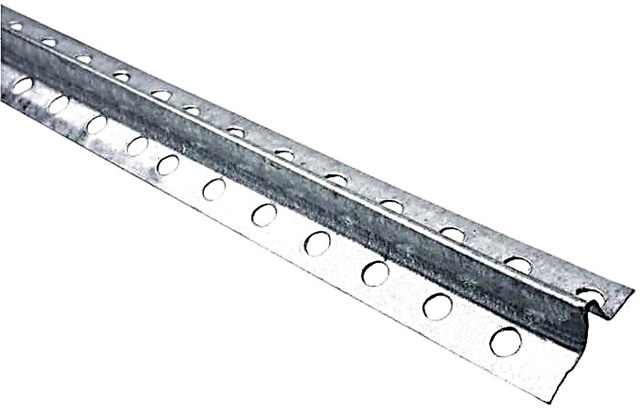

It is used as racks during the installation of doorways in partitions; it is made of high-quality steel with high resistance to corrosion. The standard sizes of the reinforced rack profile for drywall (mm):

- length - 3000, 4000, 6000,

- the height of the side parts is 40,

- base width - 50, 75, 100,

- workpiece thickness - 2.

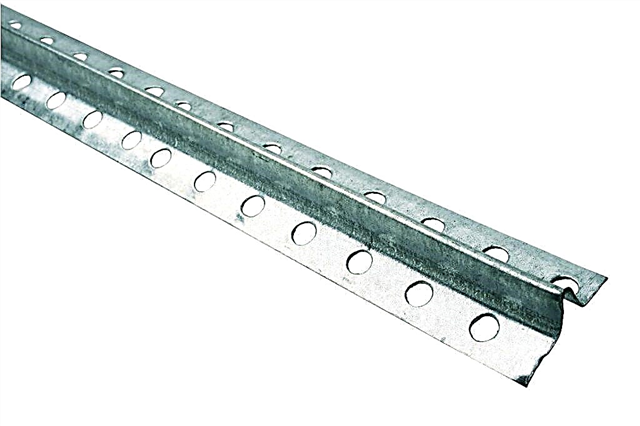

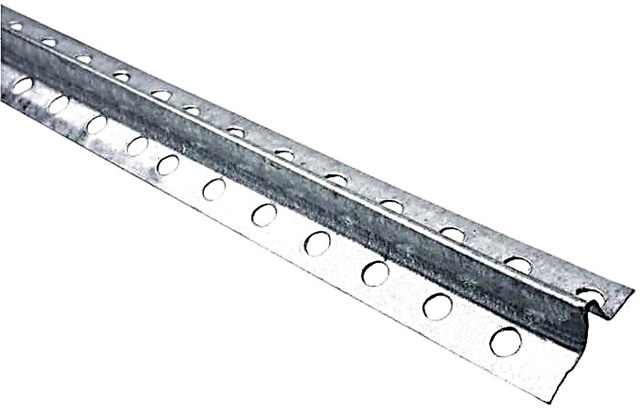

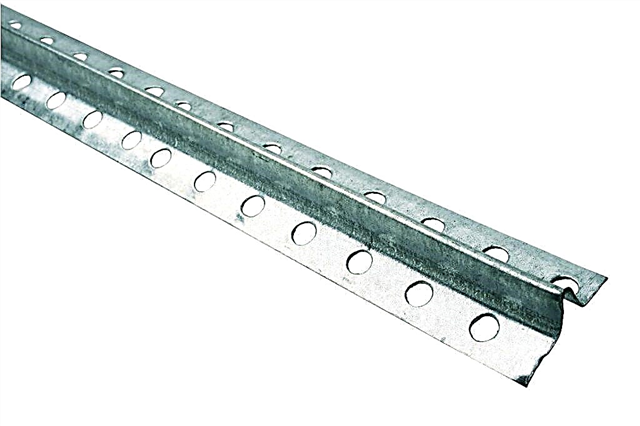

Corner - PU (protective)

The part is mounted on the external corners of the structure, being their protection against possible damage during operation. The shelves of the element are equipped with openings into which the finishing solution penetrates (putty or plaster), providing more durable contact with the surface. Dimensions of angular metal profiles for drywall (mm):

- length - 3000,

- section - 25x25x0.4,

- 31x31x0.4,

- 31x31x0.5.

Corner - PU (plaster)

It is mounted on the corners of the openings, the ends of the partitions and other surfaces that will be plastered. As well as protective, it has openings for the penetration of finishing solutions (previously applied to the corner of the structure) and is made of galvanized steel, resistant to corrosion. Standard plasterboard dimensions for drywall (mm):

- length - 3000,

- section - 35x35.

It is used as a support guide base in order to obtain a smoother surface during finishing work on plastering. The material of manufacture is high-quality galvanized steel, which has excellent anti-corrosion properties. Among modern specialists in the repair of residential and industrial premises, the most common beacon profile for gypsum plaster of the following sizes (mm):

- length - 3000,

- section - 22x6, 23x10 and 62x6.6.

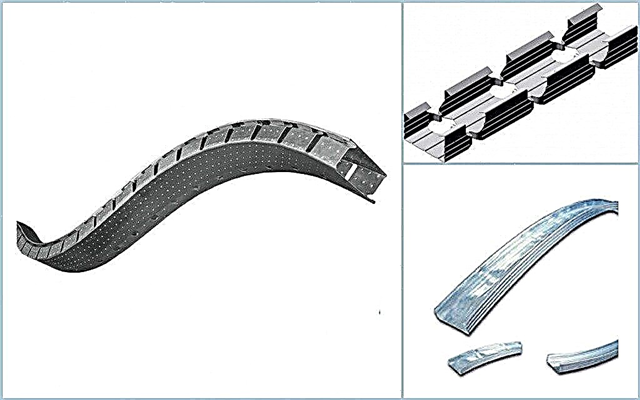

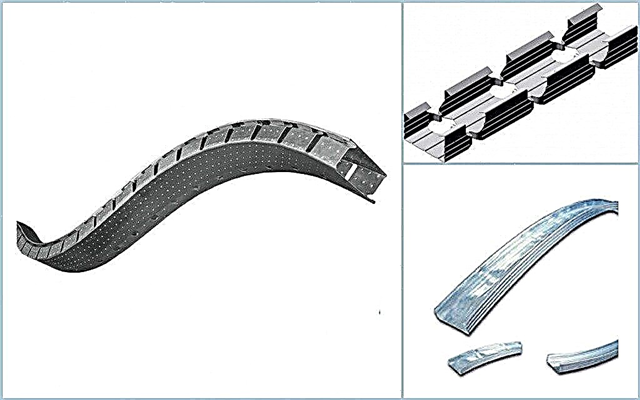

Most often, this element is made of PP 60/27, which we described in one of the previous sections of the article. It is of two types and is used in the installation of the frame for non-standard "curved" ceiling structures based on gypsum plaster, as well as arches, columns and domes of this material. The main difference of the product: if necessary, it can be easily bent with a smooth arc. The arched profile for drywall has dimensions (mm):

- the length of the "concave" - 3000,

- "Convex" - 6000,

- bending radius (min.) of the "concave" - 500,

- "Convex" - 1000.

It should be noted that professional and experienced craftsmen involved in the decoration of premises with the use of gypsum plaster, use only proven and well-proven materials in their work.

One of the quality standards is the products of the German company KNAUF, according to the classification of which this review was prepared. All of the above types and sizes of metal profiles for drywall you can easily find under the company logo of this famous brand.

Fasteners and accessories

In addition to the described elements, when installing the frame and fixing its base to the ceilings, some standard parts are used that need to be prepared before performing the work:

- Direct suspension - fastens the ceiling (PP) and rack (PS) profiles for drywall to the wall and ceiling (Figure 1).

- Anchor suspension - they attach the PP to the ceiling, have a clamp and traction, which allow you to adjust the position of the structure in height (Figure 2).

- Extension cord - used when docking (connecting) metal strip strips in various combinations (Figure 3).

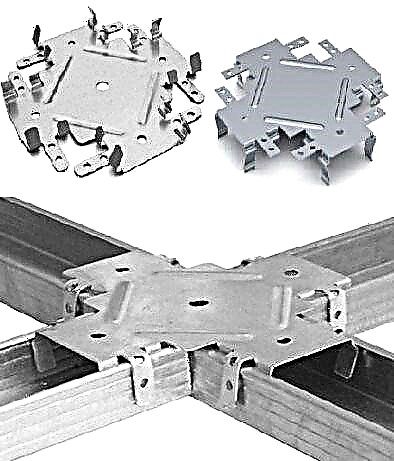

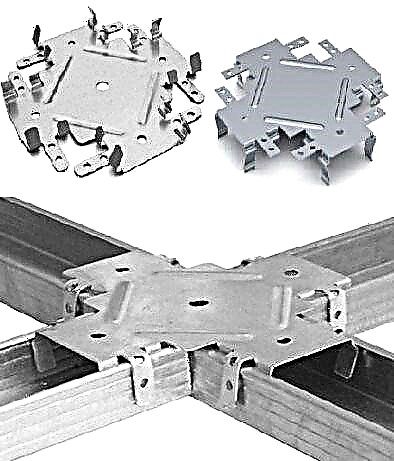

- Single-level crab connector - can connect all types of metal profiles for drywall in cross-shaped (strictly 900) structural elements. It is most often used for fastening PP at the same level when mounting the battens on the ceiling (Figure 4).

- Two-level connectors - fasten PP strips perpendicular to each other at different levels (Figure 5).

- Anchor dowels and self-tapping screws - with their help, all frame elements of the metal profile are fastened together and are securely fixed to the main floors of the room (Figure 6).

As can be seen from our study, in such a case that is not easy at first glance, such as arranging a GKL structure, everything is thought out and calculated to the smallest detail. One has only to have a desire and be patient - the result will exceed all expectations. Dare, and if you have questions about the method of mounting the frame, the type or size of profiles for drywall - feel free to contact us, here you will receive qualified and competent help.

Materials: what profiles are made for GCR

A profile for drywall of any kind is made of steel and aluminum. Steel (ordinary or galvanized) is more common, since aluminum, although they have excellent characteristics, are very expensive.

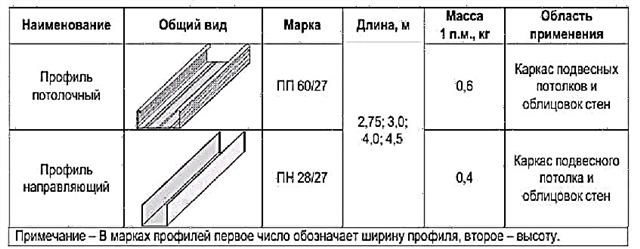

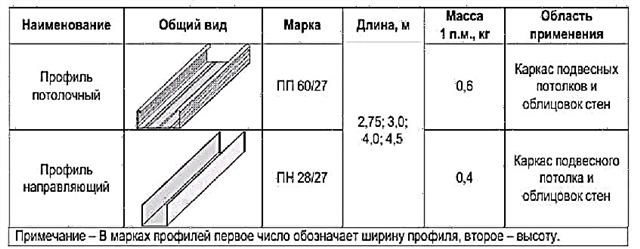

These are the main types of profiles for GKL

Steel can be ordinary or with a protective layer - galvanized. Conventional - made of black steel - have a lower cost, suitable for rooms with normal operating conditions. With their help, they make a suspended ceiling, walls and partitions, arches in living rooms, corridors. In rooms with high humidity - bathrooms, kitchens, etc. - it is better to use galvanized steel or aluminum.

To create wireframes

There is a profile for drywall of the following types:

- Guide. It is designated as PN (UD) (decoding - profile guiding). The section is U-shaped, with smooth side walls. It is used as a support base for racks and jumpers. Mounted around the perimeter of the structure, then all other elements of the system are installed in it. Dimensions:

- 28 * 27 mm

- 50 * 40 mm

- 65 * 40 mm,

- 75 * 40 mm

- 100 * 40 mm.

The guide profile for drywall can be distinguished by smooth shelves

Rack profile for drywall has additional stiffeners and shelves

The ceiling profile is also guide and bearing. Differ in smaller sizes (in comparison with wall)

These are all types of profiles for drywall, which are used to build the frame. A “frame” is assembled from the PN guides, racks of PS are inserted into them, which are then connected by jumpers (usually from the PN) - for greater structural rigidity.

Additional profiles and accessories

There are several types of additional profiles that are used in finishing work, when creating a suspended frame for the ceiling, for attaching rack profiles to walls, etc.

- Angular. In section - a right angle with a slightly protruding central part. Used to decorate the corners of drywall constructions. There are several types:

- Both shelves are perforated with large holes - so that the corner becomes part of the plaster, due to which they hold.

- Corner profile for gypsum board with mesh. A mesh strip can be glued to the edges of the perforated corner - for better adhesion with subsequent finishing.

- On a paper basis - two metallized strips are glued onto thick paper. They are used in unloaded places - they make up window openings, edges of niches, shelves and other similar products.

Corner profile - for the formation and protection of corners of drywall constructions

Perforated suspensions and methods of their use

Anchor suspension - for easy adjustment of the height of the suspended ceiling

Connectors - single-level and two-level

Most of these devices can be dispensed with. For example, two profiles are spliced with a piece of a guide profile of a suitable size. It is inserted inside, squeezed with pliers shelves, screwed with screws. The connection is more rigid than with special devices.

How to connect / build a profile for drywall

When creating a frame located along the wall, it is fixed not with perforated suspensions, but with boots - sections of profiles bent in the form of the letter “G” (called “boot” - in a characteristic shape).

Two ways to fix the rack profiles to the wall - using a perforated suspension and a piece of profile

This is not so much a way to save as an opportunity to get a tougher mount, since perforated suspensions were originally designed for suspended ceilings and can hardly withstand the load from drywall wall, and even laid in two rows.

Profile Length

The drywall profile of each species may vary in length. Standard lengths are 2.4 and 2.8 meters. but there are up to 4 m.

An example of assembling a frame for a suspended ceiling made of gypsum plasterboard

Should I look for long profiles? There is no big sense in this. Is that the assembly of the frame will accelerate a little. The profiles under the GCR are perfectly fused, the structural strength does not suffer. Only when assembling the frame it is necessary to make sure that the joints at adjacent racks are not at the same level. Usually, the joints are made alternately at the top, then at the bottom.

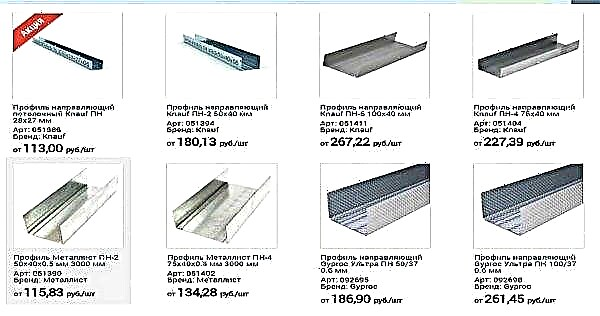

How to choose a profile for GKL

In a more or less large construction store or even on the market, there are profiles for drywall of the same type and length, but with a significant difference in price. The cost may differ twice, and sometimes more. Moreover, the most expensive are usually Knauf, the cheapest are anonymous China, the middle range is domestic producers.

In addition to the type and size of the profile for drywall, you must also choose the thickness of the metal and manufacturer

Metal thickness

The difference will become clear as soon as you pick up the profile. Some are durable, rigid, made of steel with a thickness of 0.5 mm, 0.55 mm, 0.6 mm and more. Others are made of such thin metal that they change their geometry even if the profile is lifted by one edge.

With this parameter, everything is more or less simple and understandable. The thicker the metal, the stronger and stiffer the profile, but the price is also higher. Optimally for creating partitions with standard wall heights, take profiles with a metal thickness of 0.5 or 0.55 mm. If possible, you can take 0.6 mm.

The sizes are standard, but the weight of the same profile may be different - due to the different thickness of the metal from which it was made

It makes sense to take a large metal thickness only if the height of the partition is large - the load will be more significant and the additional strength will not hurt. But in this case, you need to look at what will be cheaper - a profile for drywall made of thicker metal or more often installed racks and crossbars. Just keep in mind that racks with a pitch of 60 cm are usually installed - so that the joint of the GKL sheets falls in the middle of one of the rack profiles. With a decrease in pitch, it is necessary to achieve the same thing - the joint of sheets of drywall should not hang in the air. So it will be possible to put them only after 40 cm. So the seam will also have to be on the profile. But this is too many racks and is unlikely to be cheaper. In general, count.

Manufacturer's choice

Choosing a manufacturer of drywall guides is both simple and difficult at the same time. All experts unanimously claim that the best are Knauf (Knauf). They always correspond to the declared parameters, have perfect geometry: the racks perfectly fit into the guides, do not hang out and do not burst them. In general, working with Knauf drywall profiles is easy, simple, the work progresses quickly. But, these are just the most expensive of the whole assortment. Despite this, the advice is this: if you have no experience with drywall - it is better to buy Knauf.

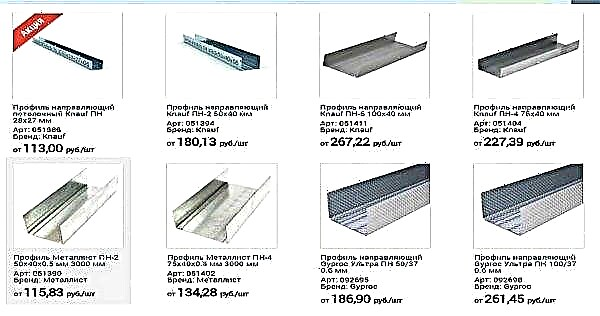

This is a screenshot of the prices for the profiles for the drywall of one of the online stores

There are several Russian firms in the average price range. These are Giprok and Metalist. There are also regional little-known campaigns. Here's how lucky. Trust your feelings and reviews. Focus on the words of sellers is not always possible. Domestic manufacturers have good lots, and fail. In most cases, there is such a problem as a mismatch in the sizes of rack-mount PSs and guide profiles. The racks must be precisely installed inside the guide. In order for the declared width, for example, 50 mm, the actual should be 1.5 mm less. Now, with the accuracy of observing this difference, problems arise. In addition, the declared thickness of the metal must be checked (micrometer). In general, you can save money, but you will spend a significant amount of your nerves and time.

GIPROK has this option

Giprok has a profile with a grooved surface. All sides of the profiles - and the back and shelves - have extruded "pimples". They increase the rigidity of the profile. This is true - the design is more rigid. But the connection of the racks and rails is more awkward - due to the mismatch of the "pimples" they are not attracted closely like smooth metal walls. There is a second point - designs from such profiles creak more. For all that, such profiles cost slightly less than Knauf, but working with them is more difficult. In general, you decide.

How to calculate the number of profiles

To know what type and type are profiles for drywall, their sizes are not enough. It is necessary to calculate the amount of each species. It will be easier to count if you draw a plan of the frame on a piece of paper, sign the names of the profiles, put down the dimensions. It will not take so much time, but it will help to more accurately determine the quantity.

You must clearly understand how the frame will look.

Calculation of the number of guides for one wall

If the walls are very uneven, they can be leveled with plasterboard. A parallel wall is arranged, but set strictly in level. In this case, the calculation of the number of profiles for drywall will be as follows:

- Guides - Mon. They are mounted around the perimeter. To find the footage of the guide profiles for wall sheathing, measure its length and height, add and multiply by 2. If there are windows / doors on the wall, the guide profile is mounted around the perimeter of these openings. To the resulting figure we add the double height of the opening and its width.

This is what the frame for the partition looks like

If all walls in a room are sheathed with drywall, a similar calculation is carried out for each wall, then the results are summarized.

The number of profiles for drywall for suspended ceiling - PP and PNP

The calculation here is a little simpler: the frame is “in a cage”, so it’s easier to calculate. Otherwise, the approach is the same as described above. So we consider:

- The footage of PP profiles for a false ceiling is equal to the perimeter of the ceiling. We measure the length and width of the room, add and multiply by 2. This will be the desired number. For example: a suspended ceiling in a room measuring 3 * 4 meters will do. Calculation of the footage of PP profiles: 3m + 4 m = 7 m, 7 m * 2 = 14 m. For this room, you will need 14 meters of PP profile.

First mounted ceiling guide rails

In total, for a suspended ceiling in a room measuring 3 * 4 meters, you will need 14 m + 20 m = 34 m of PP profile, 21 meter of PNP profile.

What can be drywall profiles.

In 1980, one owner of a paper mill named Ostug Sackett came up with the idea of creating new gypsum building material. At first, plywood and chipboard were replaced in small houses with plasterboard sheets. It was then that discovered the interesting properties of this material. The joints of smooth and even cardboard are very easy to seal so that when painting or other types of finishes, they will be completely invisible. Breaking a marked sheet, instead of sawing it, is much easier. The constant size eliminates cracks in the joints ... Drywall has proven itself in the construction market for a long time and has remained an integral part of the repair to this day.

That, or another drywall construction, always rests on the frame of strong and stable parts. These are guides and profiles of various shapes that are interconnected using special fasteners. They vary in purpose and application, as well as in size and quality. It is very important to make the right choice when buying, the result of the work will depend on this. Indeed, if you take a profile that is bad or simply not suitable for a certain type of work, the structure will eventually have to be redone. For example, a sheet on the partition will bend or “go” to the side, gaps at the joints will become visible, or a noticeable “wave” will appear on the wall itself. In order to avoid mistakes during repair and construction, it is necessary to study the types and sizes of profiles for drywall well. Find out what kind of material is needed for the construction of a particular structure.

Rack profile (designated as: CD or PP).

Perhaps one of the most sought-after profiles for installing drywall on the ceiling. This type provides reliable fastening of sheets. And if you select the dimensions correctly, then the work space will be used as economically as possible, leaving almost no waste.

Sizes of CD or PP:

- Profile length - from 2.5 to 4 meters

- Width - 60 mm

- Shelf height - 27-28 mm

Guide (UD or PPN).

Profiles are used for the construction of a false ceiling. They mount these elements over the entire area of work, because fixing the sheets of cardboard, the drill passes directly through them. It is advisable to purchase guides that already have cut holes (perforated profiles). Then it will be much easier to carry out the installation.

- Thickness - 0.55 mm

- Length - 3 meters

- Width - 27 mm

- Height - 28 mm

Guide Profiles (UD).

This type is suitable not only for ceilings, but also for plasterboard partitions and wall cladding. Let's consider in more detail: in the back of these products there are holes for dowels (8 millimeters). Profiles are in the form of the Russian letter "P", and also vary in size.

Dimensions: (the first digit is the width of the back, the second is the width of the shelf)

- 50 x 40 millimeters

- 65 x 40 millimeters

- 75 x 45 mm

- 100 x 40 millimeters

Rack Profile (CD).

For partitions, this view has special grooves along the shelf. The two extreme ones are intended for screwing in self-tapping screws, and the one in the middle indicates the place of joints of drywall sheets. The width of the rack backs is identical to the guides. Because the PS is inserted into the PN.

- 50 x 50 millimeters

- 65 x 50 millimeters

- 75 x 50 millimeters

- 100 x 50 millimeters

Reinforced (UA).

The profile is used for doorways in partitions. The main quality is durability and corrosion resistance.

- length - from 3 to 6 meters

- side height - 40 mm

- base width - 50 - 100 mm

- workpiece thickness - 2 mm

Corner - (PU protective).

Designed to protect the corners and ends of drywall partitions from mechanical damage. There are holes on the surface of the profile so that the finish solution penetrates into them.

- Length - 3 meters

- Section - 25x25x0.4 mm, 31x31x0.4 mm, 31x31x0.5 mm

Beacon Profile (PM).

It is used for finishing work. Fastened with mortars to the required level. It helps to putty (or plaster) the wall evenly.

- Length - from 2.5 to 3 meters

- Width - from 22 to 60 millimeters

- Metal thickness - from 0.33 to 55 millimeters

- Beacon protrusion - from 6 to 10 millimeters

Arched profile (PA) for drywall. Sizes and types.

This profile has cuts along the edges, due to which the metal product can be bent evenly and adapted to the construction of almost any complex structure. For example, make an arch or shelf in the wall, an unusual shape. There are both concave and curved types of arched profile.

Sizes of concave arch profiles:

- Radius from 500 to 5000 millimeters

- Length from 2600 to 4000 millimeters

Convex profiles can be:

- Radius from 1000 to 5000 millimeters

- Length from 400 to 2600 millimeters

Aluminum profile and its features.

Such a profile is not cheap, but it has an excellent characteristic, so the high price is justified. Such profiles are good for building window frames or decorating household appliances. For example, if you need to make a niche for a washing machine in the bathroom. This product is distinguished by a long service life, durability and lightness. It does not burden the entire structure and is very easy to mount. Plastic and resistant even to low temperatures. Builders recommend buying an aluminum profile for wall and ceiling cladding.

Profiles of this type come in both from cold aluminum and from warm. Cold-formed made of metal with a thickness of 4 mm, while bending without heating. It differs in form (П, Ш, Т, Н - shaped). It can withstand loads up to 1.5 kN per 1 meter of wall.

Galvanized profile.

The galvanized profile is not inferior in price to aluminum. It is used to build the base of the frame, in rooms of high humidity - in the kitchen or in the bathroom. That's because, it is resistant to rust and does not require additional treatment with anti-corrosion agents. Like aluminum, the profile is light and soft, screwing screws into it will not be difficult. Galvanization is also used to create additional stiffening ribs if the drywall sheets are thicker than 12.5 millimeters.

There is also a plastic profile. Its purpose is to close the joints of drywall sheets at external corners, giving a beautiful appearance to the finish. And also, they cover the transition of drywall and other material, such as wood.

Additional accessories for attaching drywall.

In order to assemble the crate, you will need auxiliary parts:

- Two-level connector for a CD profile. Such a part is sold in an unfolded, flat form and before starting work it must be bent in the shape of the letter P. It is used to connect rack parts that are perpendicular to each other.

- A single-level connector for a CD profile or Crab. They also connect perpendicular CD profiles. If the load is more than 20 kilograms, then two screws will be needed for fastening. Otherwise, the terminations are simply bent.

- Direct suspension for the rack (bearing) profile. This is a bracket with a standard length of 12.5 cm. It looks like a strip of aluminum or galvanized steel, with holes. It withstands loads of up to 40 kilograms. It is attached to the wall with two dowel-nails, then the edges are bent and the frame parts are already attached to them.

- Anchor suspension for ceiling carriers. Often called - suspension with traction. Replaces the above described part if its length is not enough. Used on horizontal surfaces, for ceiling, for example.

- Extension. It is necessary to connect two carriers with each other. On the sides has tubercles, this is the designation of the profile docking point. There are also two holes for screwing in screws.

- Corner connector. They connect elements that do not form a cross. You can do without a connector. Trim the shelves of the profile that you want to connect, so that a tongue forms, and screw it with screws.

Accessories for drywall fasteners.

Self-tapping screws are needed to connect all parts of the frame and for the installation of drywall. They also come in many forms.

- Self-tapping screws LB9 (11, 16) and LN9 (11, 16). The numbers after the name indicate the length of the screw. Type LB is drilling, and LN is piercing. Builders call this type of product "bugs." These "bugs" have a convex hat, and this interferes with the snug fit of the drywall to the frame.

- Self-tapping screws TN25. These screws fasten the sheets to the profiles. They have a flat hat, so that when the wall is primed, it can be easily hidden. There are also long self-tapping screws of this type, they are needed if, to increase the strength, it is required to fasten two sheets at once.

- Self-tapping screws with a press washer. Suitable for working with any materials. They can be either drilling or piercing type. It is long from 9 millimeters to 10 centimeters.

- Self-tapping screws with dowels. Guides are attached to the enclosing structures. The range of these elements is large, which one to choose depends on the material of the ceiling or wall and the size of the profile.

- Ceiling wedge anchor. This fittings fasten anchor suspensions to the ceiling.

- Dowel nail. The length of the product is from 40 millimeters to 60. It is used to fix the frame to a brick or concrete wall. To make it easier to do this, you can hammer the screws with a hammer, and not screw them in.

Tips for choosing a profile and accessories for drywall.

- Carefully inspect the profile before buying. If you notice rust, then you should refuse to buy such material. If corrosion has already begun, it is impossible to stop it!

- Check the thickness with a vernier caliper. If it turns out to be insufficient, then at work, the screws will scroll.

- Do not take a burr profile. In the process, wound your hands.

- Look closely at the product from the end. If it is not properly stored in the store, then it may be bent. With such a profile, you will no longer be able to create a perfectly even surface of the structure.

- Keep in mind that in the profile, where there is a weak notch, it will be difficult to screw the screws.

- Experienced builders are advised to double-check whether the sizes correspond to those stated in the instructions and in reality. Some manufacturers are deceiving customers, especially about the length, it can be less than expected, by 2 centimeters.

- It is necessary to check the quality of mounting hardware. Very often, self-tapping screws with a broken tip or with clogged metal notches for a screwdriver come across.

- Have a good look at the plastic plugs of the dowels so that there are no sagging, otherwise they will be difficult to drive into the hole, and sometimes even impossible.

- Prefer, nevertheless, to a profile with point perforation along the bar - it is more rigid and resistant to stress. This structure prevents the sliding of screws, and makes it possible to screw them at any angle.

- Trust already trusted manufacturing companies such as Knauf and Gyprok. But there are also our, domestic manufacturers, which produce a profile for drywall no worse.

- Some cunning sellers try to hide defects by coloring the profile and adding shine to it. Take a closer look at such options, maybe it’s not at all possible to buy them.

- The product should not be flimsy and bend when pressed slightly.

And the last tip in concluding the article. Do not save on high-quality profiles and accessories for them. As the famous saying goes: "Avaricious pays twice." If you get a poor-quality or damaged profile, then eventually, sooner or later, you will have to redo all the work. Somewhere, the sheet will rise “hill”, somewhere the joints will become visible, and somewhere the structure will bend inward. Therefore, choose the material carefully, pickiness will not be superfluous here. Good luck and easy work!

Profiles for cladding ceilings and walls

Considering the types and characteristics of drywall, you need to dwell on the structural elements, without which its installation is impossible.

When creating wall and ceiling structures, two types of galvanized steel profiles are used - UD and CD. You cannot build a curved surface without an arched profile. All of the listed profile elements have standard cross-sectional sizes. The differences between them are only in the length and thickness of the metal used.

UD - guide profile for drywall. It is designed to create a mounting plane and is placed along the contour of the future suspended ceiling or wall cladding. A CD carrying profile is embedded in it. It forms the frame of the crate, to which drywall is attached.

The width of the UD profile is 28 mm and the height is 27 mm. The length is presented in two versions: 3 and 4 meters. Wall thickness depends on the manufacturer and can range from 0.4 to 0.6 mm.

When deciding which profile is needed for drywall, first of all pay attention to the thickness of the metal. Elements made of thin steel (0.4 mm) can only be used for wall cladding. Thick metal (0.5-0.6 mm) will hold the suspended ceiling system securely.

CD - supporting flat profile. It is used to form the skeleton and assumes the bulk of the load. This structural element is responsible for the spatial rigidity of the frame and serves as the basis for fastening drywall.

The width of the CD profile is 60 mm, the height is 27 mm. Standard lengths are offered by manufacturers in two sizes: 3000 and 4000 mm.

A flat profile is good for everyone, except for one point: it is impossible to create a basis for covering an arched opening or a curved surface from it. Manufacturers solved this problem very simply: they took a standard CD bearing profile and made curly cuts and holes in it. So we got an arched profile, the dimensions of which completely coincide with the width and height of the carrier.

The mounting dimensions of the profile for arched drywall: width 62 mm, height 27 mm with a length of 3 or 4 meters. You can bend this profile not only inward, but also outward. The bending radius should not be less than 50 cm.

Some companies, such as Knauf, offer a ready-made curved convex or concave arched profile designed for dome structures and curved ceilings. This is a regular factory-made CD profile.

Partition Profiles

They are marked with the symbols UW (guide), CW (carrier or rack). Compared to planar profiles, these elements have a large width and height.

Their main size range is as follows:

- Bearing CW -50/50 mm, 75/50 mm, 100/50 mm, 125/50 mm, 150/50 mm,

- Guide UW - 50/40 mm, 75/40 mm, 100/40 mm, 125/40 mm, 150/40.

Variations in the length of the supporting rack profile 2.6 - 4.0 meters. The standard guide length is 4000 mm. The cross-sectional profiles noticeably differ from planar ones in the cross-sectional shape.Two longitudinal ribs are rolled on them, increasing the rigidity of the wall, and in the rack they make an H-shaped cut for skipping cable lines.

Guiding profiles for UW gypsum board are used to define the mounting plane of the wall and install supporting profiles. They are mounted around the entire perimeter of the partition (on the walls, on the floor and ceiling).

Rack profile CW is used to form the frame. It is most often installed in increments of 40 cm so that the seams of the drywall sheets fall onto its surface.

Another area of application for reinforced CW and UW profiles is gypsum plasterboard suspended ceiling, where the highest spatial rigidity is required from the frame. Here their functions remain the same: creating a guide plane (UW) and a bearing crate (CW).

Briefly about the installation of profiles

As we have already said, the guide profile under the drywall serves as the “baseline” that defines the plane of the sheathed surface. It is attached to the walls and ceiling with dowels and screws.

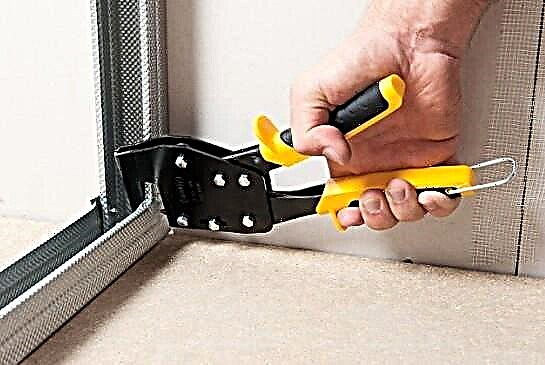

To assemble a node from the guide and bearing profiles, two methods are used:

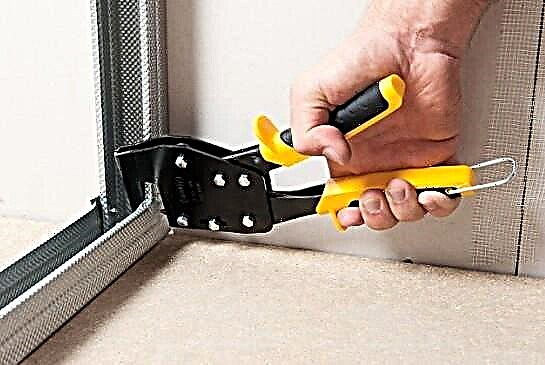

- Self-tapping screws ("fleas"),

- Mechanical screener.

The latter method of interconnecting profiles speeds up the assembly process, eliminating the manipulation of a screwdriver. However, it has one drawback: it is rather difficult to disassemble such a connection (analogue of a rivet) if necessary.

For fastening the supporting profile to the wall or ceiling, direct plate or pin (sliding) suspensions are used.

To connect the bearing profiles in the perpendicular direction, one-level or two-level “crabs” are used - rectangular stamped plates.

Indicative prices

Prices for the metal profile for the installation of drywall vary significantly depending on the size and thickness of the metal. We will consider market offers by standard features.

The UD guide profile (length 3 meters, metal thickness 0.5 mm) can be purchased for 60-90 rubles. The supporting CD profile of the same length and thickness is sold for 80-130 rubles.

Average prices for a wall guide profile UW (PN) with a length of 3 meters look like this:

- 50x40x0.4 mm - from 60 to 70 rubles.,

- 75x40x0.4 mm - 80-90 rubles.,

- 100x40x04 mm - 90-110 rubles.,

A 0.6 mm thick profile is 25-30% more expensive on average.

Estimated cost of rack-mount CW (SP) profile (3 meters):

- 50x50x0.4 mm - 80-90 rubles.,

- 75x50x0.4 mm - 100-110 rubles.,

- 100x50x0.4 mm - 120-130 rubles.